- +8615880211820

- [email protected]

- Tongan sanoat parki, Xiamen

| Mahsulot nomi | Antibakterial Masterbatch |

| Tashqi ko'rinish | Oq granula |

| Antibakterial darajasi | 99% |

| Faol modda | Zirkonyum kumush fosfat antibakterial vosita |

| Samarali qattiq tarkib | 20% |

| Ichki yopishqoqlik | 0.52 |

| Zichlik | 1.0 |

Iste'mol tovarlari, to'qimachilik va sanoat materiallarida gigiena, tozalik va uzoq muddatli antibakterial himoyaga bo'lgan talab ortib borayotgani ilg'or mikroblarga qarshi qo'shimchalardan foydalanishni tezlashtirdi. Bular orasida, Zirkonyum kumush fosfat antibakterial masterbatch barqarorligi, xavfsizligi va kuchli keng spektrli antibakterial imkoniyatlari bilan ajralib turadi. Plastmassa va kimyoviy tolalar uchun ishlab chiqilgan bo'lib, u uzoq muddatli ishlashni ta'minlaydi va standart ishlab chiqarish tizimlariga osongina integratsiyalanadi.

Ushbu masterbatch bilan tuzilgan zirkonyum fosfat tashuvchisi tomonidan quvvatlangan kumushga asoslangan antibakterial vositalar, nazorat ostida va barqaror antibakterial faollikni ta'minlash. Ichkarida an'anaviy plastik granulalar bilan aralashtirilganda, uni turli antibakteriallarga qayta ishlash mumkin plyonkalar, choyshablar, tolalar, va kalıplanmış materiallar.

Zirkonyum fosfat matritsasiga kiritilgan kumush ionlari asta-sekin va barqaror ravishda chiqariladi, bu materialning yuzasiga mahsulotning butun umri davomida bakteriya o'sishiga qarshilik ko'rsatishga imkon beradi. Ushbu barqaror bo'shatish mexanizmi ajoyib antibakterial chidamlilikni ta'minlaydi va uni gigienaga yo'naltirilgan ilovalar uchun juda mos qiladi.

Noyob sirkonyum fosfat tashuvchisi kumush ionlarining boshqariladigan chiqarilishini ta'minlaydi, bu antibakterial ta'sirning plastik yoki tolali mahsulotning o'zigacha davom etishiga imkon beradi. Bu butun xizmat muddati davomida barqaror himoyani ta'minlaydi.

Yigiruv darajasidagi polimerlar uchun mo'ljallangan, masterbatch mukammal eritish ko'rsatkichlarini saqlaydi. Bu qiladi rangsizlanishiga olib kelmaydi, va tayyor tolalar saqlaydi yuqori oqlik, uni to'qimachilik va kiyim-kechak ilovalari uchun ideal qiladi.

Kuchli issiqlikka chidamliligi bilan masterbatch yuqori haroratli ishlov berish sharoitida ishonchli ishlaydi. Bu sarg'ishlikka moyil emas, hatto takroriy isitish davrlarida ham barqaror ko'rinish va ishlashni ta'minlaydi.

Masterbatch kuchli antibakterial faollikni namoyish etadi, uni yo'q qilishga qodir 650 dan ortiq turdagi bakteriyalar. Uning sterilizatsiya darajasiga etadi 99.99%, uni kundalik ishlatiladigan mahsulotlarda uchraydigan keng tarqalgan patogenlar va mikroorganizmlarga qarshi samarali qilish.

Zirkonyum kumush fosfat antibakterial Masterbatch uzoq muddatli antibakterial xususiyatlar muhim bo'lgan keng tolali va plyonkali ilovalar uchun javob beradi. U keng qo'llaniladi:

Kiyim va kiyim-kechak matolari - yaxshilangan gigiena va hidga chidamlilik uchun

Oyoq kiyimlari uchun materiallar - astarlar, ichki tagliklar, to'rli matolar va poyabzal komponentlari

To'shak va uy to'qimachilik – matraslar, yostiq uchun plombalar, ko‘rpa-to‘shaklar

Tashqi makon va turmush tarzi mahsulotlari – ryukzaklar, sayohat jihozlari, lager materiallari

Arqonlar va sanoat tolalari - xavfsizlik arqonlari, dengiz arqonlari, ko'p maqsadli arqonlar

Pardalar va ichki to'qimachilik - uylar, mehmonxonalar, maktablar, shifoxonalar va jamoat joylari uchun

Ushbu ilovalar masterbatchning chidamliligi, oqligi va barqaror antibakterial ishlashidan, hatto yuqori haroratli ishlov berish sharoitida ham foyda keltiradi.

The Zirkonyum kumush fosfat antibakterial masterbatch uzoq muddatli antibakterial himoya izlayotgan ishlab chiqaruvchilar uchun materialning ishlashini buzmasdan ideal echimni taklif qiladi. Uning barqarorligi, sarg'aytirmaydigan xatti-harakati, yuqori oqligi va kuchli bakteritsid ta'siri uni tolalar, plyonkalar, choyshablar va gigienaga yo'naltirilgan keng turdagi plastik mahsulotlar uchun juda mos keladi.

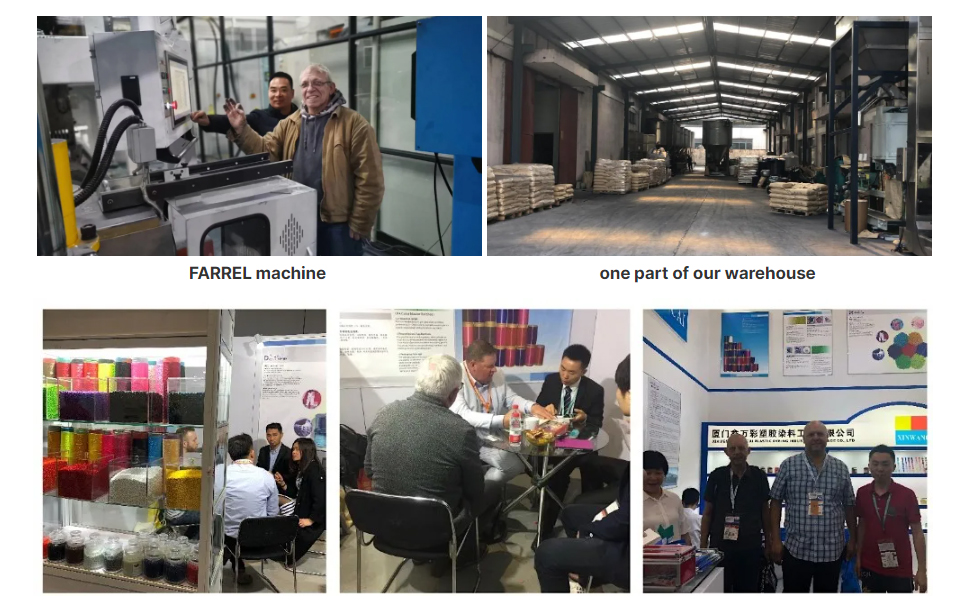

Bizning kompaniyamiz 20 yildan ortiq plastik masterbatch sanoatida ishlaydi, biz Xitoyning Xiamen shahridagi Tong'an sanoat parkida joylashgan Rangli masterbatch, funktsional masterbatch, shisha tolali mustahkamlangan plastmassa va yonishga chidamli plastik xom ashyoni tadqiq qilish va ishlab chiqarishga ixtisoslashganmiz.

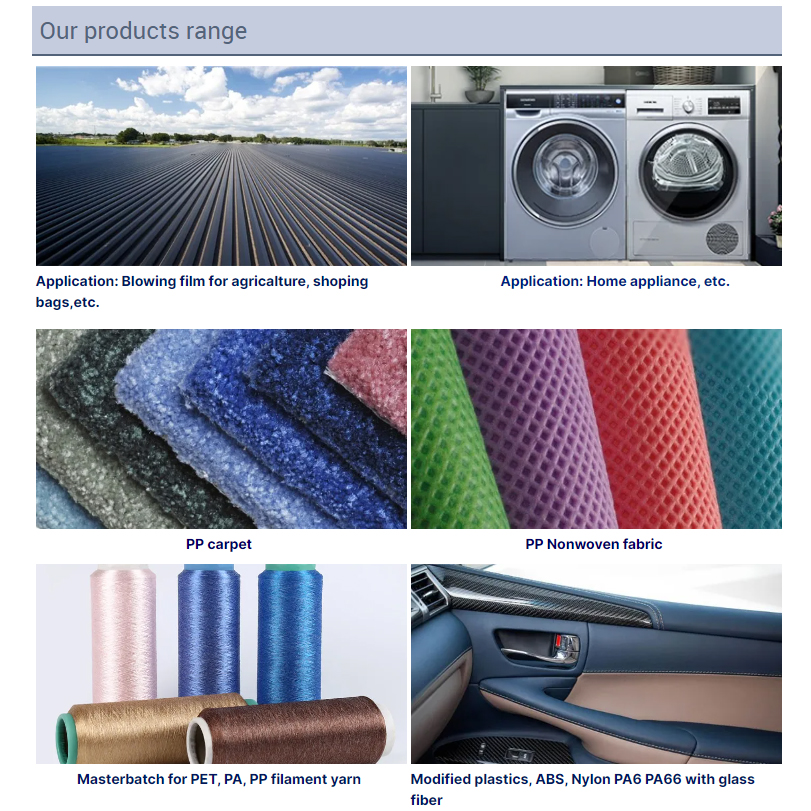

Xulosa qilib aytganda, biz plastik masterbatchning barcha turlarini ishlab chiqarishda professionalmiz, jumladan qo'shimchali masterbatch, funktsional masterbatch, pe olovga chidamli masterbatch, ABS olovga chidamli masterbatch, anti-kislorod masterbatch, anti-UV masterbatch, antibakterial masterbatch, antiblock masterbatch , va ba'zi boshqa qo'shimchalar masterbatches.

Bizning masterbatchlarimiz turli sohalarda ko'plab ilovalarni topadi. Plastmassa, to'qimachilik yoki turli ishlab chiqarish jarayonlarida bo'ladimi, bizning masterbatchlarimiz mahsulot sifati va samaradorligini oshirishda muhim rol o'ynaydi. Sozlanishi mumkin bo'lgan formulalar bilan ular ranglarning mustahkamligi, UV himoyasi, olovga chidamliligi va boshqalarni taklif qiladi, bu ularni son-sanoqsiz ilovalar uchun asosiy yechimga aylantiradi. Avtomobil qismlaridan qadoqlash materiallarigacha, bizning masterbatchlarimiz sanoatning keng spektrida yuqori natijalarga erishish uchun ishonchli tanlovdir.

Bizning maxsus masterbatchlarimiz tanlangan materialga kiritilganda optimal ishlashni ta'minlaydigan maxsus polimerlarga mos ravishda ishlab chiqilgan. Biz quyida aytib o'tilgan turli xil polimerlar uchun mos bo'lgan masterbatchlarni ishlab chiqarish imkoniyatiga egamiz va yana ko'p. Agar siz bu erda ro'yxatda bo'lmagan material bilan ishlayotgan bo'lsangiz, iltimos, maxsus ehtiyojlaringizni qondirish imkoniyatini o'rganish uchun bilimdon texnik guruhimizga murojaat qilishdan tortinmang.

Past zichlikdagi polietilen - HDPE dan biroz shaffofroq va sezilarli darajada egiluvchan, asosan moslashuvchan qadoqlash, sumkalar, egiluvchan quvurlar, plyonkalar va shunga o'xshash maqsadlarda qo'llaniladi. HDPE singari, u cheklangan shaffoflik xususiyatlariga ega. U spirtlar, kislotalar va ishqorlarga nisbatan ajoyib kimyoviy qarshilik ko'rsatadi, ammo uglevodorod erituvchilar va mineral moylarga nisbatan cheklangan qarshilikka ega. UV nurlanishiga uzoq vaqt ta'sir qilish degradatsiyani boshlashi mumkin.

Yuqori zichlikdagi polietilen - Bir oz sutli-oq ko'rinishga ega bo'lgan ushbu material qattiq shisha qadoqlash, in'ektsiya bilan qoplangan qopqoq va qopqoqlar, qutilar va boshqalarda keng qo'llaniladi. Uning tabiiy shaffofligi erishish mumkin bo'lgan shaffoflik darajasini cheklashi mumkin. HDPE LDPE bilan solishtirganda yuqori kimyoviy va erituvchiga qarshilik ko'rsatadi.

PPCO Random & PPHO - O'rtacha tiniqlikka ega bo'lgan polimer, qopqoq va yopish ishlab chiqarishda qo'llaniladi. Bundan tashqari, u uy-ro'zg'or buyumlari, chelaklar, o'yinchoqlar va saqlash idishlarini tayyorlash uchun ishlatiladi. Polipropilen rang yoki maxsus effektlarda sezilarli cheklovlarsiz moslashuvchanlikni ta'minlaydi. Tasodifiy sopolimer gomopolimerga nisbatan ko'proq tiniqlikka ega va shaffof soyalarni yaratish uchun ko'proq mos keladi.

PPCO bloki - PPCO ga o'xshash, ammo zarba qarshiligini oshirish uchun yaxshilangan. Qo'shimcha polimerni oq rangga aylantiradi, bu esa yuqori shaffoflikka olib keladi. Bu xususiyat erishiladigan shaffoflikni cheklashi mumkin.

Polietilen tereftalat (PET) - Polyester materiallari mukammal kimyoviy qarshilik va to'siq xususiyatlari bilan birga mustahkam mexanik kuchga ega. Gazlangan ichimliklar idishlarini ishlab chiqarish uchun PET tez-tez tanlanadi. Bundan tashqari, polyester yigirilib, kiyim-kechak uchun to'qimachilik ishlab chiqarishda ishlatilishi mumkin. PET juda shaffof bo'lib, uni shaffof qadoqlash uchun ajoyib tanlov qiladi, garchi "sarg'ish" ning nozik ishorasi juda ochiq ranglarga ta'sir qilishi mumkin.

Polibutilen tereftalat - elektronika sohasida izolyatsion material sifatida tez-tez ishlatiladigan kristalli termoplastik muhandislik polimeri. Ushbu modda poliester toifasiga tegishli bo'lib, atributlar va ishlov berish sifatining ajoyib muvozanatini namoyish etadi.

Umumiy maqsadli polistirol - shishadek tiniq ko'rinishga ega, ammo minimal zarba qarshiligiga ega bo'lgan ushbu material CD qutilarida asosiy qo'llanilishini topadi. Uning sezilarli tiniqligi uni shaffof ranglar yaratish uchun mos qiladi, garchi vaqti-vaqti bilan binafsha rangni sezish mumkin.

Yuqori ta'sirli polistirol - zarbalarga chidamliligini oshirish uchun ta'sirni kuchaytiruvchi vositani o'z ichiga olgan GPPSdan olingan. Ushbu qo'shilgan komponent polimerning oq rangga aylanishiga olib keladi va turli formulalar turli darajadagi shaffoflikni ta'minlaydi. Odatda o'yin qismlari, o'yinchoqlar va shunga o'xshash narsalarni ishlab chiqarishda qo'llaniladi. Uning aniq oqligi shaffof rang berishni maqsad qilganda qiyinchiliklarga olib kelishi mumkin. GPPS bilan bir xil shaffoflik darajasiga erishish uchun K-Resin va Styrolux kabi ixtisoslashtirilgan alternativalar bozorda mavjud.

Akrilonitril butadien stirol (ABS) - Yuqori ta'sirli polistirolning (HIPS) yanada mustahkam iteratsiyasi yuqori qiymatli komponentlarda qo'llaniladi. ABS HIPS tomonidan ishlab chiqarilgan komponentlarga nisbatan ancha chidamliligini namoyish etadi, garchi u shaffof ranglarga erishishga urinayotganda shunga o'xshash qiyinchiliklarga duch keladi. Xuddi HIPS singari, ABS ham maxsus shaffof variantlarni taklif etadi. Chidamliligi tufayli ABS odatda elektr asboblari uchun korpuslarni tayyorlashda qo'llaniladi.

Poliamid (6, 66) - Neylon mexanik qurilish va texnik xizmat ko'rsatishda keng qo'llaniladigan ko'p qirrali sinfdir. Uning mashhurligi mexanik kuch, qattiqlik, mexanik damping xususiyatlari va samarali elektr izolyatsiyasi imkoniyatlarining ajoyib aralashmasidan kelib chiqadi. Shunday qilib, neylon elektr korpuslarini ishlab chiqarish uchun afzal qilingan materialdir. PA66 kimyoviy va fizik atributlari PA6 ga juda o'xshash bo'lgan turli xil ilovalarda metallga umumiy muqobil bo'lib xizmat qiladi. PA6 namlikni yutish uchun yuqori sezuvchanlikka ega bo'lsa-da, yuqori zarba qarshiligi va erituvchilarga qarshilik ko'rsatadi.

Stirol akrilonitril kopolimeri - Shaffoflik va ajoyib kimyoviy va issiqlik qarshiligiga ega, SAN shuningdek, yaxshi qattiqlik, valentlik va egilish kuchiga ega. Yuqori porloq qoplamasi tufayli SAN odatda kosmetik qadoqlash uchun tanlanadi. Biroq, SAN yordamida ochiq rangdagi ranglarga erishish, ishlab chiqarish jarayonida uning vizual ko'rinishini yaxshilash uchun ishlatiladigan materialga xos bo'lgan binafsha rang bo'yoqlari tufayli qiyin bo'lishi mumkin.

Polietilen tereftalat glikol - glikolni o'z ichiga olgan PET. Ushbu glikol qo'shilishi oqim xususiyatlarini yaxshilaydi, lekin kuchini pasaytiradi. PETG shishalarni yaratish uchun ekstrudirovka qilinishi mumkin va "blister" uslubidagi qadoqlash uchun choyshablarga aylantirilishi mumkin.

Termoplastik elastomer (TPE) yoki termoplastik poliuretan (TPU) - TPU avtomobil asboblar paneli, g'ildirak g'ildiraklari, elektr asboblari, tibbiy asboblar, shuningdek, turli xil ekstrudirovka qilingan plyonka, qatlam va profil ilovalari kabi ilovalarda turli xil foydalanishni topadi. TPElar avtomobilsozlik, tibbiyot, qurilish, elektrotexnika, maishiy texnika, qadoqlash va sanoat sohalarida keng ko'lamli dasturlarda qo'llaniladi.

Bizning masterbatchimiz haqida tez-tez so'raladigan savollar

©2023. Masterbatch ishlab chiqaruvchisi barcha huquqlar himoyalangan.

Bizning jamoamiz 20 daqiqada eng yaxshi taklifni qaytaradi.