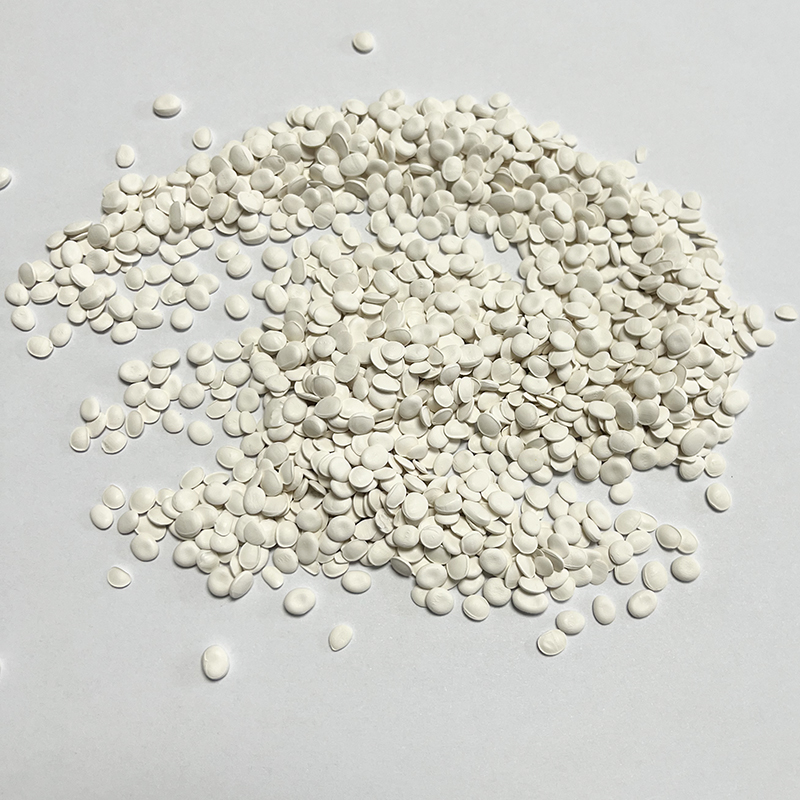

What Is Halogen-free Flame Retardant Masterbatch?

Halogen-Free Flame Retardant Masterbatch is a flame retardant masterbatch free of halogen. It can be processed into film, board, and other plastic products. Flame Retardant Masterbatch features strong dispersibility, excellent mechanical properties, and is environmentally friendly.