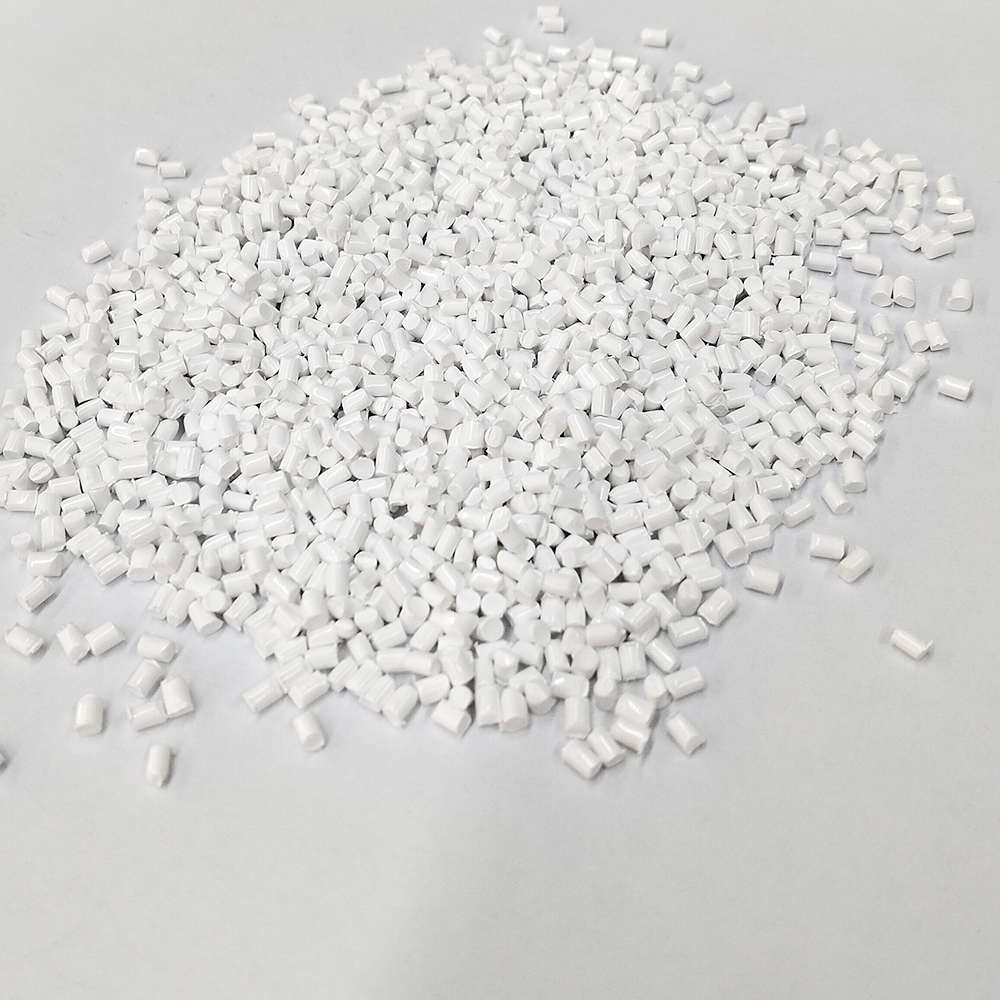

راهنمای نهایی برای مستربچ سفید: تقویت پلاستیک با شفافیت و سفیدی بالا

در دنیای همیشه در حال تکامل پلاستیک ها، مستربچ سفید نقش مهمی در بهینه سازی کیفیت و عملکرد محصولات پلاستیکی ایفا می کند. این مقاله به اهمیت مستربچ سفید، کاربردهای آن و تأثیر آن بر صنعت پلاستیک می پردازد.