1. Mélange-maître absorbant les infrarouges

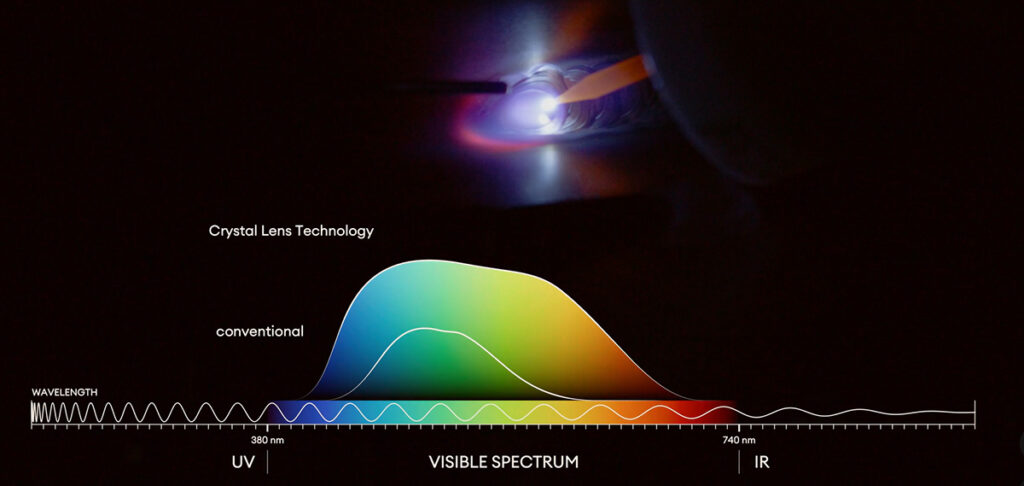

Notre mélange-maître absorbant les IR Ces formulations laissent passer les rayons infrarouges de courte longueur d'onde tout en empêchant la fuite des rayons infrarouges de grande longueur d'onde. Cela contribue à retenir la chaleur dans les espaces clos et à améliorer le confort thermique.

Applications clés :

Feuilles de polycarbonate à rétention de chaleur pour les serres et les puits de lumière

Films pour vitres conçu pour maintenir la chaleur intérieure pendant les mois les plus froids

Films et lunettes de protection laser à usage industriel ou médical

Avantages:

meilleure rétention de chaleur

Amélioration de l'efficacité énergétique

Réduction des coûts de chauffage

2. Mélange-maître réfléchissant les infrarouges

Conçu pour contrôle de la chaleur et réflexion solaire, notre mélanges-maîtres réfléchissants IR Elles réduisent la température de surface en réfléchissant des longueurs d'onde infrarouges spécifiques. Elles sont idéales pour les produits qui nécessitent surfaces froides au toucher et gestion thermique.

Applications clés :

Films pour vitres automobiles et architecturales pour réduire l'accumulation de chaleur

plaques de toiture en polycarbonate pour des environnements intérieurs plus frais

panneaux extérieurs et façades exposé à la lumière directe du soleil

Avantages:

températures intérieures plus basses

Durée de vie du produit prolongée

Économies d'énergie grâce à la réduction de l'utilisation de la climatisation

3. Mélange-maître transparent à l'infrarouge (détectable dans le proche infrarouge)

Notre mélanges-maîtres transparents à l'infrarouge sont optimisés pour systèmes de détection NIRCette innovation permet aux recycleurs d'identifier et de trier efficacement les plastiques noirs ou foncés, favorisant ainsi la durabilité de la production et du recyclage des plastiques.

Applications clés :

Feuilles de polycarbonate ou de PET noires détectable par les scanners NIR

Matériaux de films pour fenêtres recyclables pour une production respectueuse de l'environnement

Avantages:

Permet le recyclage automatisé

Favorise le respect de l'économie circulaire

Améliore le profil de durabilité de la marque