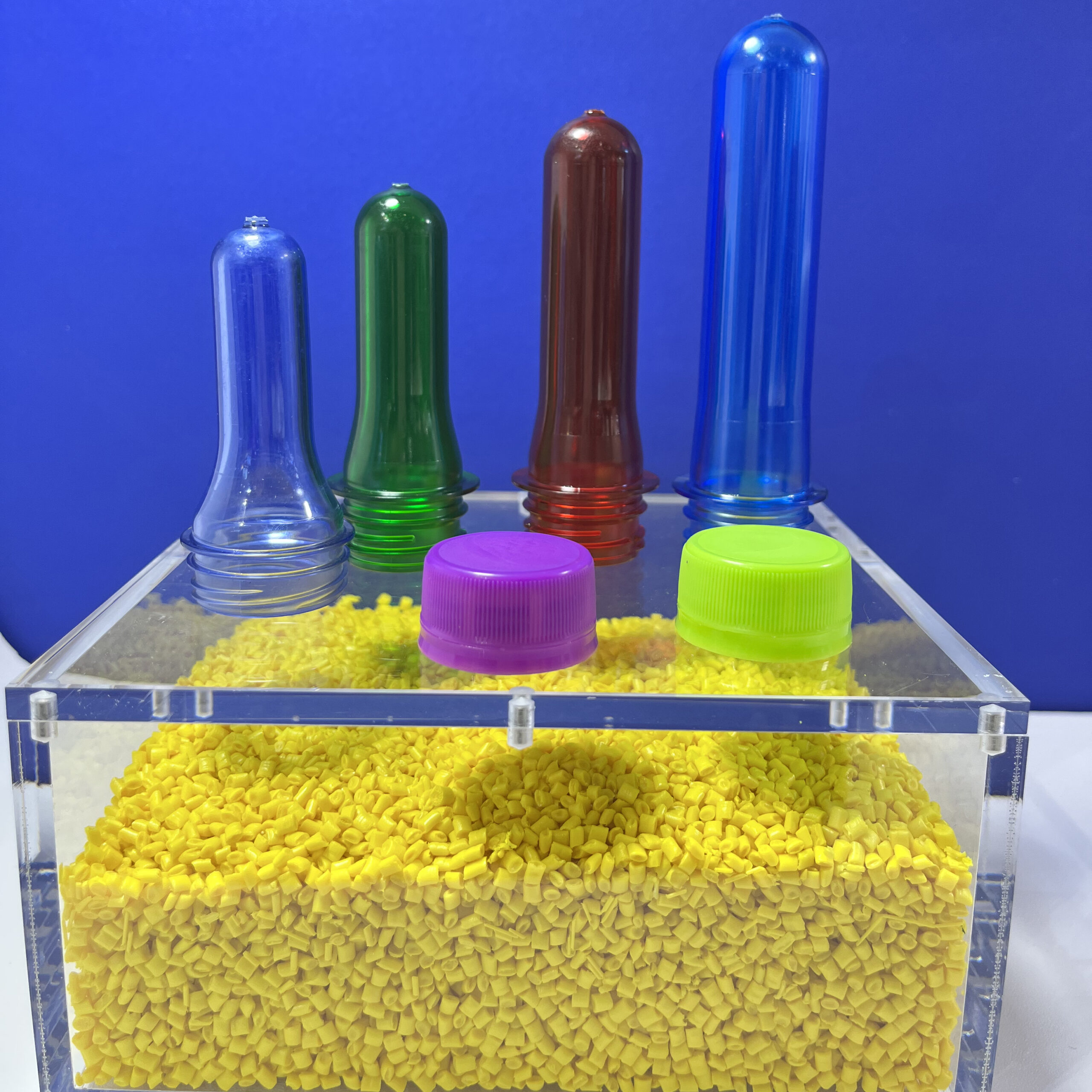

L’importance de la sélection optimale des supports pour les mélanges maîtres PET et PC

Dans le domaine du développement de mélanges maîtres, le matériau de support passe souvent au second plan, malgré son rôle central. Il sert de base sur laquelle les additifs et les pigments sont incorporés, et le bon choix de support peut apporter des avantages substantiels.