BOPET Masterbatch: The Future of High-Performance Polyester Film

BOPET masterbatch is a specialized material used to enhance the performance of biaxially-oriented polyethylene terephthalate (BOPET) films.

In the realm of 3D printing, the utilization of masterbatch plays a pivotal role, serving as a catalyst for achieving consistent coloration and enhanced material properties. This article delves into the significance of masterbatch in the 3D printing industry, shedding light on its composition, applications, and the myriad benefits it bestows upon the manufacturing process.

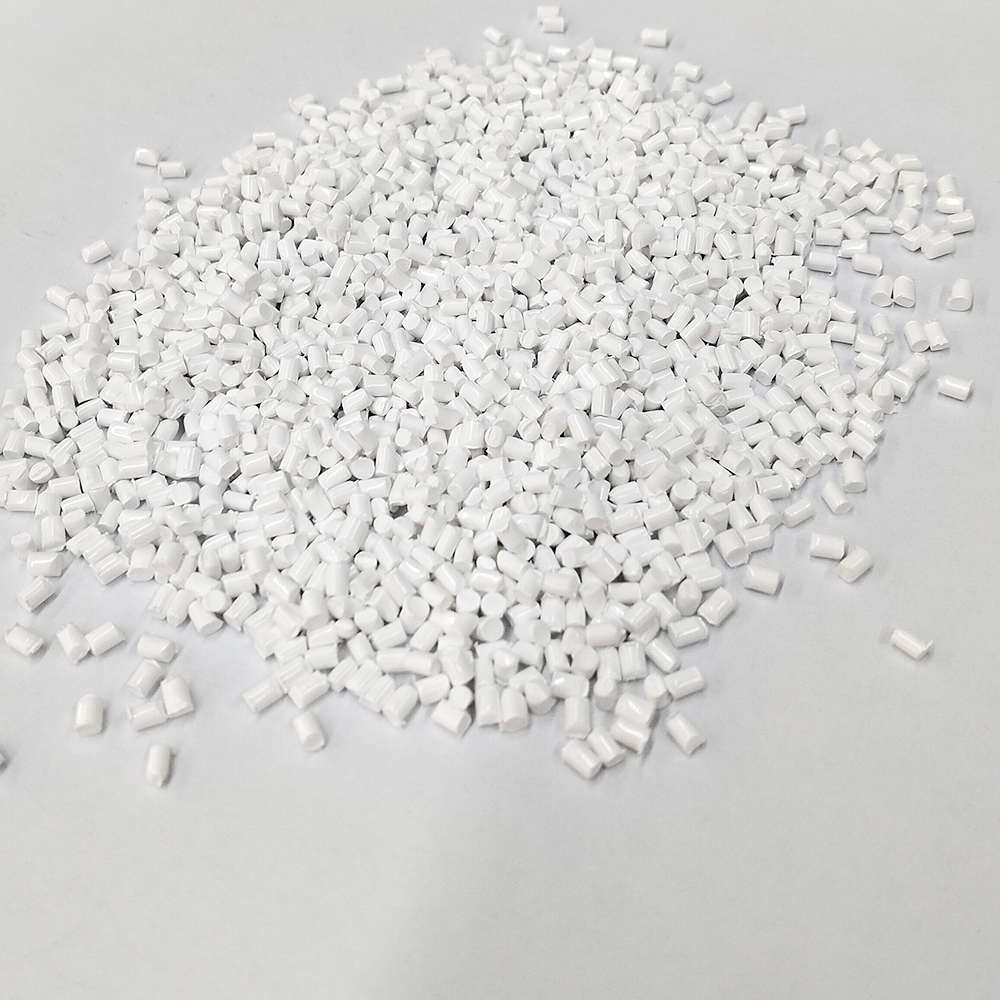

Masterbatch acts as the secret ingredient that elevates the visual and functional aspects of plastic products in the 3D printing realm. It is a concentrated amalgamation of pigments and/or additives seamlessly incorporated into the plastic resin during the manufacturing process. Analogous to adding a pinch of salt or a dash of hot sauce to enhance flavors, masterbatch imparts consistent color and specific properties to the final 3D printed products, without the need for excessive pigments or additives.

In the realm of 3D printing, masterbatch is a versatile tool utilized to either color the material or augment its inherent properties. For instance, a masterbatch containing UV stabilizers can be introduced to a plastic resin, elevating its resistance to sunlight and other forms of UV radiation. Similarly, a masterbatch enriched with fire retardants can enhance the fire safety properties of the printed material.

Enhanced Properties: Masterbatch serves as a means to enhance the properties of the printed material, offering improvements in UV resistance, fire safety, and more.

Cost-Effectiveness: The incorporation of masterbatch in the 3D printing process contributes to cost-effectiveness, ensuring that the final product adheres to requisite quality standards without inflating production costs.

Quality Improvement: By introducing masterbatch, the quality of the final 3D printed product is heightened, thanks to the addition of UV stabilizers, fire retardants, and other additives that refine material properties.

Ease of Use: Masterbatch seamlessly integrates into the 3D printing process, allowing for straightforward addition to the plastic resin before extrusion or injection molding, ensuring simplicity and efficiency.

Customizability: Masterbatch is highly customizable, catering to the specific needs and requirements of diverse industries and applications within the realm of 3D printing.

High-Quality Assurance: Opting for masterbatch from a reputable manufacturer, such as Masterbatch Manufacturers in China, guarantees that the final 3D printed product meets stringent quality standards and exhibits superior quality.

In the Chinese market, Masterbatch Manufacturers emerges as the premier choice for masterbatch solutions, offering a comprehensive range suitable for various applications, including 3D printing. Backed by a team of experts, the company assists in selecting the right masterbatch for specific applications, providing technical support and guidance throughout the production process. Renowned for high-quality products, competitive pricing, and excellent customer service, Masterbatch Manufacturers stands as a reliable partner for 3D printing endeavors.

In conclusion, masterbatch emerges as an indispensable component in the 3D printing process, facilitating manufacturers in achieving uniform coloration and optimal material properties while maintaining cost-effectiveness. For those looking to enhance the color or properties of their 3D printed products, the inclusion of masterbatch from a reputable manufacturer like Masterbatch Manufacturers in China proves to be a judicious choice.

Learn more knowledge and trends in masterbatch industry from our blog.

BOPET masterbatch is a specialized material used to enhance the performance of biaxially-oriented polyethylene terephthalate (BOPET) films.

In the ever-evolving world of plastics, white masterbatch plays a crucial role in optimizing the quality and performance of plastic products. This article delves into the significance of white masterbatch, its applications, and its impact on the plastic industry.

Xiamen Xinwancai Masterbatch is a top-tier supplier of premium white masterbatch in China, offering high-quality PE white masterbatch ideal for use in film production, packaging, and agricultural mulch films, all while maintaining competitive pricing.

©2023. Masterbatch Manufacturer All Rights Reserved.

Our team will send back the best offer in 20 minutes.