Meneroka Dunia Masterbatch Hitam dan Kelebihannya

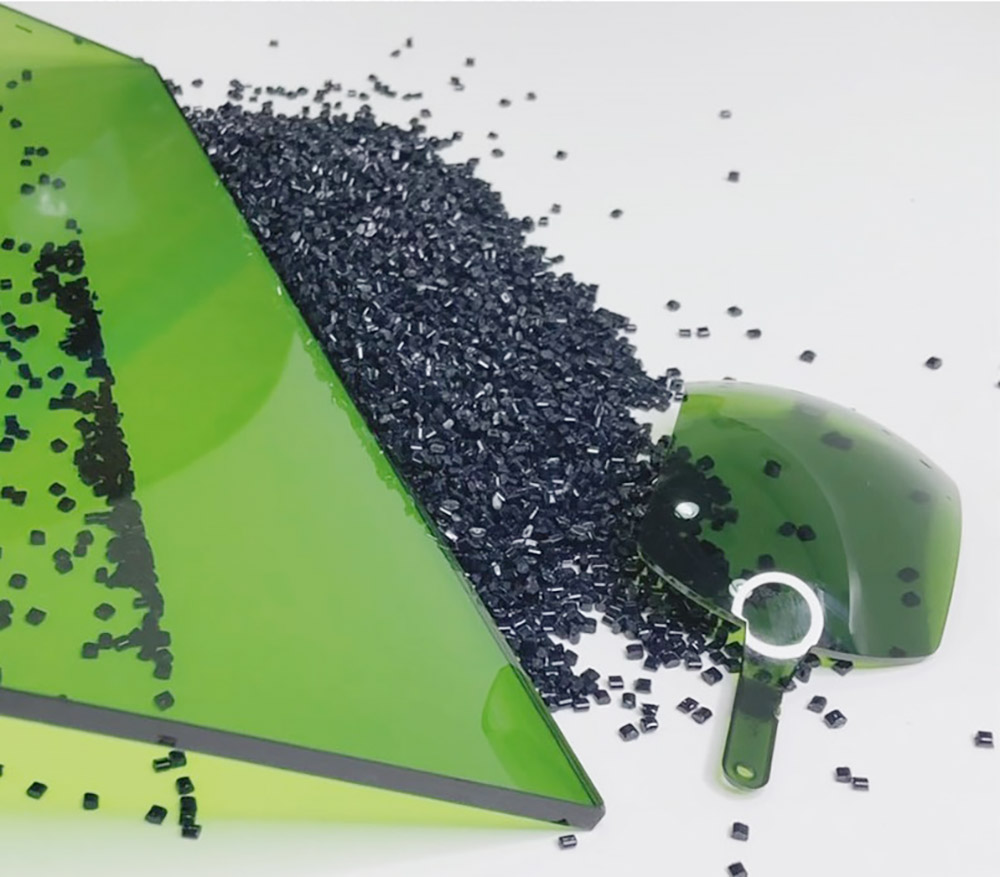

Masterbatch hitam, bahan tambahan kepekatan hitam karbon tinggi antara 15% hingga 50%, menjadi tumpuan utama dalam blog yang memfokuskan industri ini. Kami akan menyelidiki peranannya dalam menyampaikan warna hitam kepada pelbagai jenis barangan harian dan mendedahkan faedah yang ditawarkannya.