What is Masterbatch and Its Advantages?

In brief, masterbatch serves as a solid plastic additive utilized for coloring plastics or enhancing their properties.

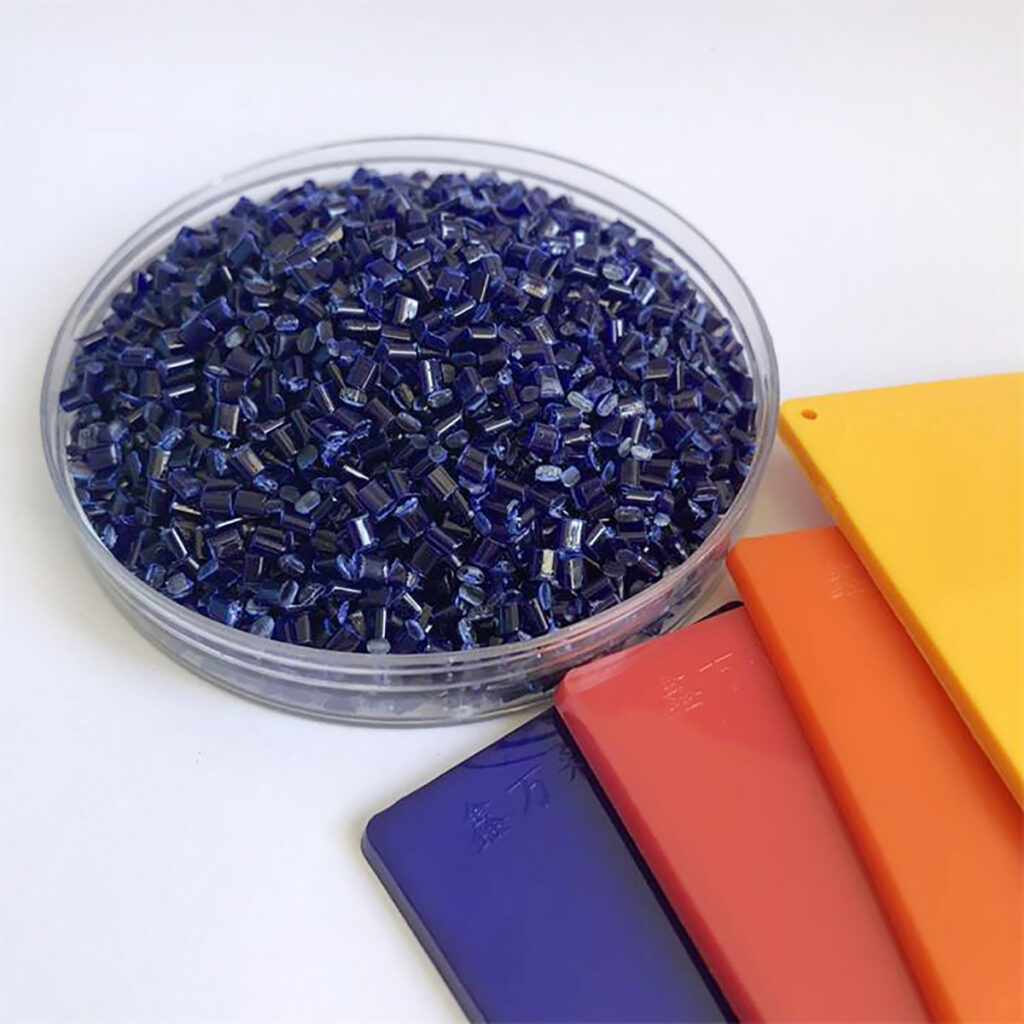

PET color masterbatch is extensively used for a wide range of products, including beverage bottles like Cola, Sprite, and green tea bottles, as well as medicine bottles in various colors (white, brown, etc.), and cosmetic packaging like shampoo bottles, perfume bottles, and cream containers. These colored plastic pellets are valued for their high quality and versatility.

When used in packaging and medicine bottles, PET color masterbatch is environmentally friendly and non-toxic, meeting both domestic and international environmental protection standards.

PET color resins are known for their excellent heat resistance, strong resistance to weather changes, and impressive durability. The color is bright, uniform, and well-dispersed, ensuring minimal color variation and meeting the diverse color needs of customers.

Beyond adhering to environmental standards, PET color pellets can be customized to create a wide range of colors to suit specific customer requirements. By using new PET material as a carrier, combined with export-grade pigments, PET masterbatch is ideal for spinning applications, enabling the creation of a variety of colors and unique designs.

PET color masterbatch also maintains chemical stability at high temperatures (up to 50°C) and in extremely cold conditions (down to -90°C). It offers superior air resistance (to O2 and CO2) compared to other high-resin materials. The material’s mechanical strength, abrasion resistance, and hardness are notable, and its products typically have a smooth, transparent appearance that is easy to print on.

However, if the temperature exceeds 100°C, PET material can produce aldehydes and antimony, which can be harmful. Some antimony compounds are linked to cancer, while others are non-toxic. PET products should generally be used only once and not recycled, as the recycling rate is low (around 20%), which ensures safety and reduces toxicity.

PET color masterbatch has a wide range of applications in the plastic manufacturing industry, including:

Iplastar is committed to developing high-quality PET color masterbatch. With professional technical engineers, advanced color testing, and a computer-assisted color matching system, we can create color masterbatches tailored to meet individual customer needs. Our advanced management system and exceptional after-sales service provide a strong foundation for fulfilling various customer requirements.

The above information highlights the importance of PET color masterbatch in plastic production. To ensure high-quality and safe plastic products, it’s essential to use top-notch masterbatch inputs. Iplastar takes pride in being a leading supplier of plastic resins on various substrates, delivering top-quality products in China thanks to superior raw materials, state-of-the-art production equipment, and an experienced team of industry specialists.

PET color masterbatch plays a crucial role in the production of high-quality, safe, and versatile plastic products across various industries. Its excellent heat resistance, durability, and environmental safety make it ideal for applications ranging from beverage bottles to packaging. Iplastar ensures that manufacturers have access to top-quality PET color masterbatch, meeting diverse customer needs with a commitment to innovation and reliability.

Learn more knowledge and trends in masterbatch industry from our blog.

In brief, masterbatch serves as a solid plastic additive utilized for coloring plastics or enhancing their properties.

In today’s competitive plastics industry, achieving high opacity, excellent whiteness, and stable processing performance is essential for manufacturers worldwide. Choosing a reliable plays a critical role in ensuring consistent product quality and cost efficiency. Xinwancai Masterbatch is a professional masterbatch manufacturer in China.

In recent times, our sensory experiences have gained prominence in influencing consumer choices, significantly impacting sales across various industries.

©2023. Masterbatch Manufacturer All Rights Reserved.

Our team will send back the best offer in 20 minutes.