What is Masterbatch and Its Applications?

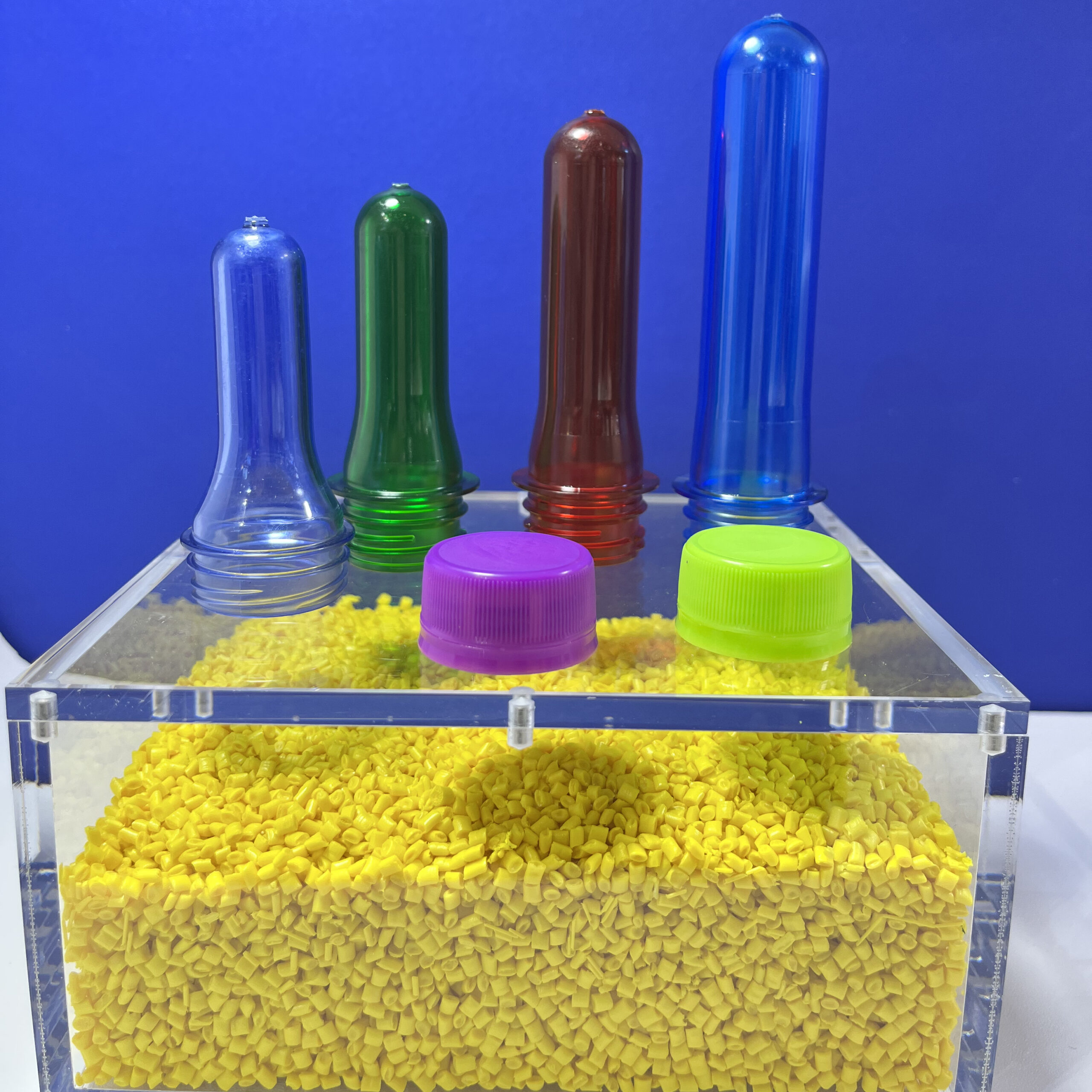

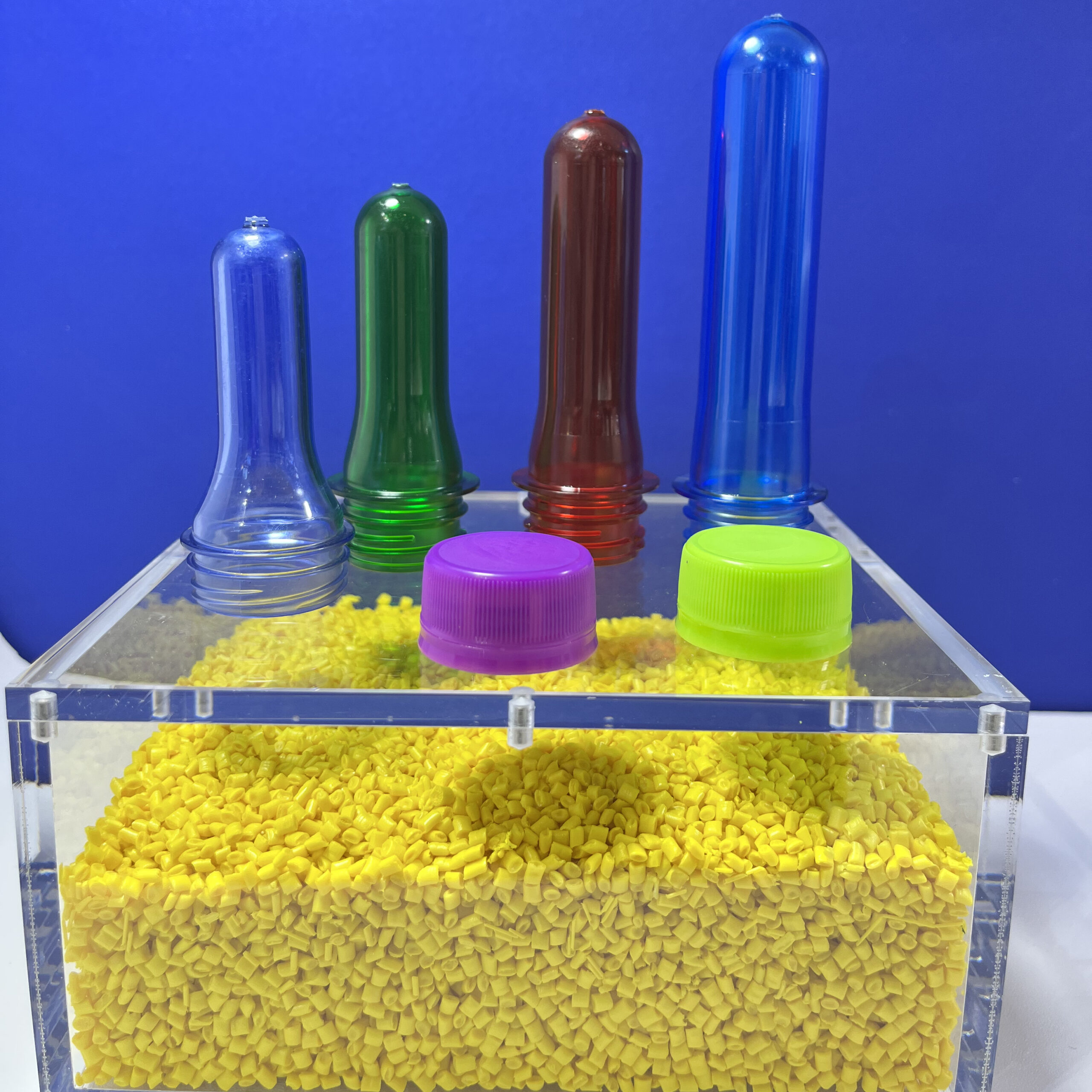

Masterbatch is a solid or liquid additive for plastic used for coloring plastics (color masterbatch) or imparting other properties to plastics (additive masterbatch).

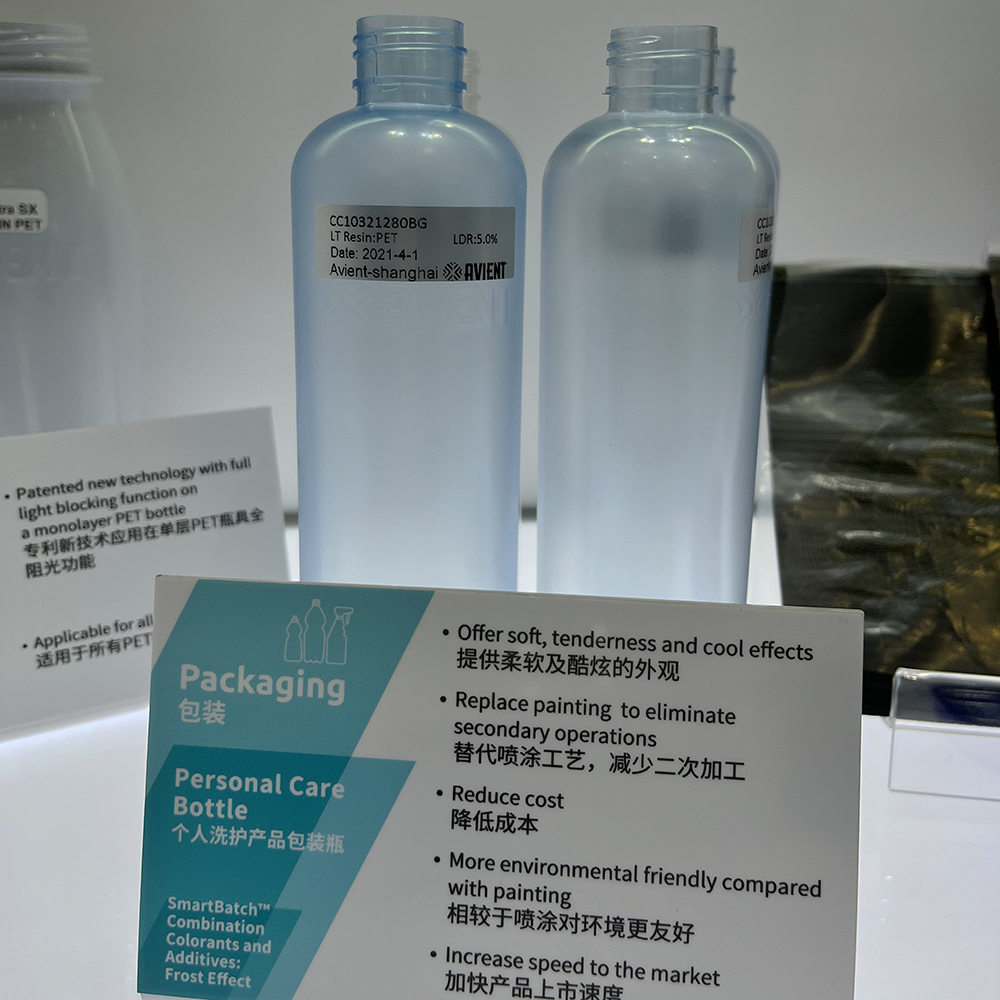

PET green masterbatch is a concentrated mixture of pigments and additives encapsulated in a polymer carrier, specifically designed for PET applications. This innovative product plays a crucial role in achieving vibrant colors and enhanced properties in plastic products.By using PET green masterbatch, manufacturers can ensure consistent color distribution and improved processing efficiency, making it an invaluable tool for modern plastic production.

The integration of PET green masterbatch in the production process allows for improved aesthetics and functionality of plastic items. When blended with virgin PET resin, the masterbatch achieves a uniform color that meets the specifications of various applications.The process includes:

“Incorporating PET green masterbatch is not just about color; it’s about enhancing the overall quality of the final product.” – Industry Expert

Utilizing PET green masterbatch offers a multitude of benefits to manufacturers and consumers alike:

By embracing PET green masterbatch, companies can enhance their product offerings while maintaining a commitment to sustainability.

The versatility of PET green masterbatch has led to its widespread adoption across various industries, including:

Each of these sectors benefits from the unique properties of PET green masterbatch, making it a vital component in modern manufacturing.

Choosing the appropriate PET green masterbatch requires a careful evaluation of several factors:

By understanding these elements, manufacturers can make informed decisions that optimize their production processes.

“Selecting the right masterbatch is critical for achieving the desired quality and performance in your end products.” – Expert Advice

PET green masterbatch contributes significantly to environmental sustainability in the plastics industry:

Through these advantages, PET green masterbatch supports the industry’s shift toward more sustainable practices.

The production of PET green masterbatch involves several key steps to ensure quality and consistency:

Understanding this process can help manufacturers appreciate the complexity and quality assurance that go into creating PET green masterbatch.

Quality assurance is vital in ensuring the effectiveness of PET green masterbatch. Key standards and testing methods include:

By adhering to these standards, manufacturers can guarantee high-quality products that meet customer expectations.

PET green masterbatch finds application in various products, showcasing its versatility:

These applications highlight the importance of PET green masterbatch in both functional and aesthetic aspects of product design.

As sustainability continues to shape the manufacturing landscape, several trends are emerging in PET green masterbatch technology:

These advancements promise to further enhance the role of PET green masterbatch in sustainable plastic manufacturing.

By understanding the significance of PET green masterbatch, manufacturers can make informed decisions that benefit both their products and the planet.Should you have further questions or need assistance selecting the right masterbatch for your needs, feel free to contact us for expert guidance.

Learn more knowledge and trends in masterbatch industry from our blog.

Masterbatch is a solid or liquid additive for plastic used for coloring plastics (color masterbatch) or imparting other properties to plastics (additive masterbatch).

In the ever-evolving world of manufacturing, the demand for innovative and efficient solutions has never been greater.

Flame retardant (FR) masterbatches are concentrated mixtures of fire-resistant additives encapsulated within a carrier resin. They are added to raw polymers during manufacturing—such as injection molding or extrusion—to delay ignition, slow flame spread, and reduce smoke generation.

©2023. Masterbatch Manufacturer All Rights Reserved.

Our team will send back the best offer in 20 minutes.