อโรมาเธอราพีในพลาสติก: เปิดตัวโลกแห่งมาสเตอร์แบทช์น้ำหอม

ในช่วงไม่กี่ครั้งที่ผ่านมา ประสบการณ์ทางประสาทสัมผัสของเรามีอิทธิพลอย่างมากต่อการตัดสินใจของผู้บริโภค ซึ่งส่งผลกระทบอย่างมากต่อยอดขายในอุตสาหกรรมต่างๆ

เมื่อวัสดุได้รับการชั่งน้ำหนักอย่างถูกต้องแล้ว วัสดุเหล่านั้นจะถูกนำเข้าเครื่องผสมและทำการผสมอย่างละเอียด กระบวนการผสมนี้ช่วยให้มั่นใจได้ว่าเม็ดสีและสารเติมแต่งจะกระจายตัวเป็นเนื้อเดียวกันทั่วทั้งส่วนผสม

จากนั้นวัสดุผสมจะผ่านกระบวนการความร้อนที่มีการควบคุม ซึ่งเรียกว่าการอัดขึ้นรูป (extrusion) ซึ่งวัสดุเหล่านั้นจะถูกหลอมรวมเป็นวัสดุพาหะ ขั้นตอนนี้มีความสำคัญอย่างยิ่งในการบรรลุคุณสมบัติและคุณลักษณะที่ต้องการของมาสเตอร์แบทช์

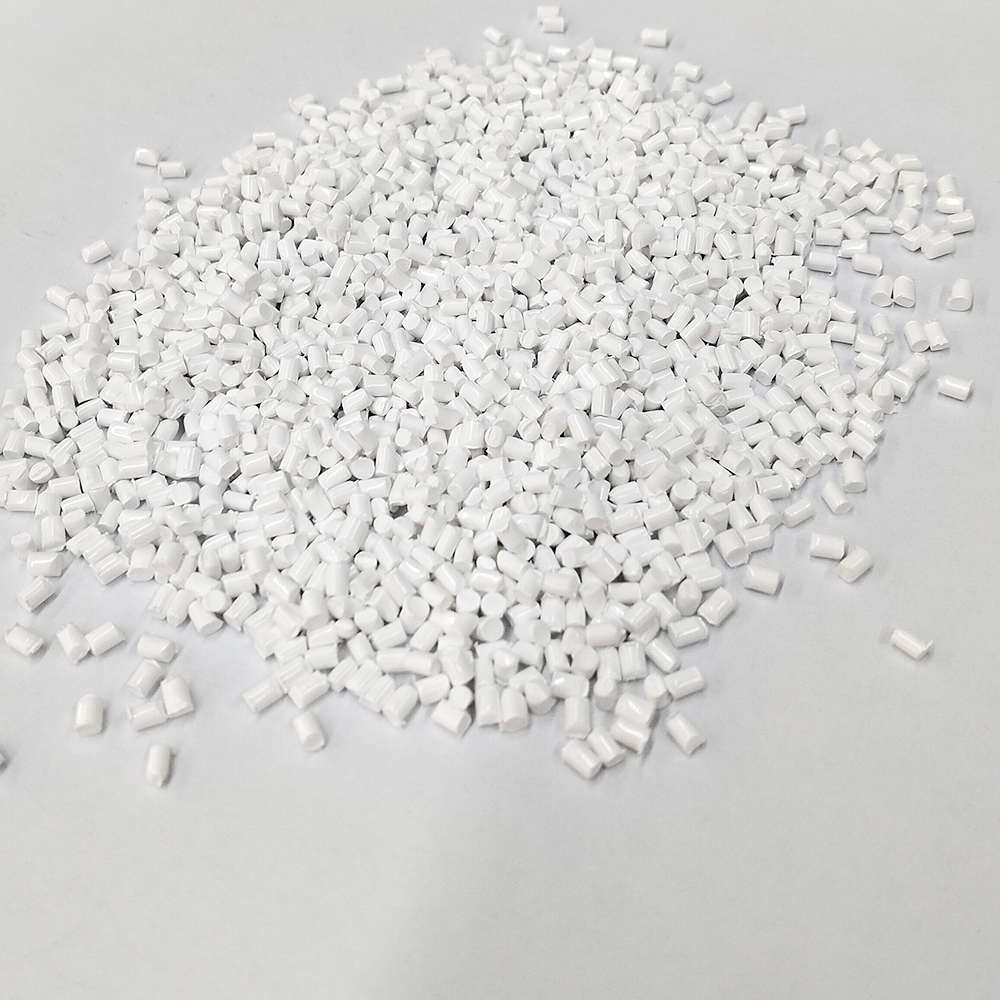

หลังจากกระบวนการอัดรีด ส่วนผสมเข้มข้นจะปล่อยให้เย็นและแห้ง ขั้นตอนการทำความเย็นและการทำให้แห้งนี้ส่งผลให้เกิดการเปลี่ยนแปลงของส่วนผสมเป็นรูปแบบต่างๆ รวมถึงผงหรือแกรนูล ขึ้นอยู่กับการใช้งานที่ต้องการ

ผลิตภัณฑ์มาสเตอร์แบทช์ขั้นสุดท้ายได้รับการบรรจุอย่างพิถีพิถันตามความต้องการเฉพาะของลูกค้า ทำให้มั่นใจได้ถึงความสะดวกสบายและความสะดวกในการใช้งานในกระบวนการดาวน์สตรีม

การผลิตมาสเตอร์แบทช์ที่ประสบความสำเร็จต้องอาศัยการพิจารณาปัจจัยสำคัญหลายประการอย่างรอบคอบเพื่อให้มั่นใจในคุณภาพของผลิตภัณฑ์ ความสม่ำเสมอ และความรับผิดชอบต่อสิ่งแวดล้อม

การรักษามาตรฐานคุณภาพระดับสูงเริ่มต้นด้วยการเลือกใช้วัสดุเกรดพรีเมี่ยม รวมถึงเม็ดสีและสารเติมแต่ง กระบวนการผลิตทั้งหมดจะต้องปฏิบัติตามมาตรการควบคุมคุณภาพที่เข้มงวดเพื่อให้แน่ใจว่าผลิตภัณฑ์ขั้นสุดท้ายเป็นไปตามมาตรฐานอุตสาหกรรม

ความยั่งยืนและความเป็นมิตรต่อสิ่งแวดล้อมถือเป็นข้อพิจารณาที่สำคัญในกระบวนการผลิตมาสเตอร์แบทช์ การเลือกวัสดุที่เป็นมิตรต่อสิ่งแวดล้อมและการนำแนวทางปฏิบัติที่ยั่งยืนมาใช้มีความจำเป็นสำหรับการผลิตผลิตภัณฑ์ที่คำนึงถึงสิ่งแวดล้อมและมีผลกระทบต่อสิ่งแวดล้อมน้อยที่สุด

เพื่อให้บรรลุถึงความสม่ำเสมอและความน่าเชื่อถือ วัสดุจะต้องผ่านกระบวนการผลิตที่แม่นยำ ซึ่งรวมถึงการรักษาสัดส่วนของวัสดุที่ถูกต้องและรับรองความสม่ำเสมอตลอดกระบวนการผลิต ควรมีมาตรการควบคุมคุณภาพเพื่อรับประกันว่าเป็นไปตามข้อกำหนดทั้งหมด

สำหรับการผลิตมาสเตอร์แบทช์สี การได้รับความแม่นยำของสีที่แม่นยำถือเป็นสิ่งสำคัญ สัดส่วนเม็ดสีที่ถูกต้องมีความสำคัญอย่างยิ่งในการได้สีที่ต้องการ และสีที่ได้ควรจะคงตัวภายใต้สภาวะต่างๆ เพื่อเพิ่มรูปลักษณ์ที่สวยงามของผลิตภัณฑ์ขั้นสุดท้าย

วัสดุมาสเตอร์แบทช์ต้องเข้ากันได้ไม่เพียงแต่เข้ากันได้เท่านั้น แต่ยังรวมถึงกระบวนการผลิตเฉพาะที่ใช้งานอยู่ด้วย ความเข้ากันได้ของวัสดุมีบทบาทสำคัญในการรับประกันความสำเร็จของมาสเตอร์แบทช์และคุณภาพของผลิตภัณฑ์ขั้นสุดท้าย

ประสิทธิภาพในการผลิตเป็นกุญแจสำคัญในการรักษาความคุ้มค่าโดยไม่กระทบต่อคุณภาพของผลิตภัณฑ์ การลดการสูญเสียวัตถุดิบและการเพิ่มประสิทธิภาพการผลิตสูงสุดเป็นกลยุทธ์ที่ช่วยให้การผลิตมีความคุ้มค่า

การปฏิบัติตามบรรทัดฐานด้านกฎระเบียบอย่างเคร่งครัดตลอดทั้งการผลิต บรรจุภัณฑ์ และการขนส่งถือเป็นสิ่งสำคัญอย่างยิ่งสำหรับความปลอดภัย การปฏิบัติตามกฎระเบียบที่กำหนดขึ้นทำให้มั่นใจได้ว่าผลิตภัณฑ์เป็นไปตามมาตรฐานความปลอดภัยและคุณภาพที่จำเป็นทั้งหมด

ตลอดกระบวนการผลิตมาสเตอร์แบทช์ การจัดลำดับความสำคัญความต้องการของลูกค้าเป็นสิ่งสำคัญ ซึ่งรวมถึงการจัดการทุกด้าน ตั้งแต่การเลือกเม็ดสีไปจนถึงการขนส่งผลิตภัณฑ์ การพิจารณาว่ากระบวนการผลิตส่งผลต่อคุณสมบัติของผลิตภัณฑ์อย่างไร รวมถึงปัจจัยต่างๆ เช่น บรรจุภัณฑ์ การติดฉลาก และการขนส่ง เป็นสิ่งสำคัญในการส่งมอบผลิตภัณฑ์ที่ตรงตามและเกินความคาดหวังของลูกค้า

การผลิตมาสเตอร์แบทช์เป็นกระบวนการที่จัดเตรียมอย่างพิถีพิถันซึ่งครอบคลุมขั้นตอนต่างๆ ซึ่งแต่ละขั้นตอนมีความสำคัญอย่างยิ่งในการผลิตผลิตภัณฑ์คุณภาพสูงและอเนกประสงค์ ตั้งแต่การชั่งน้ำหนักวัสดุที่แม่นยำและการผสมเม็ดสีอย่างละเอียด ไปจนถึงการอัดขึ้นรูป การทำความเย็น และบรรจุภัณฑ์ที่ออกแบบโดยเฉพาะ ทุกขั้นตอนมีส่วนช่วยในการสร้างมาสเตอร์แบทช์ที่ตอบสนองความต้องการที่หลากหลายของอุตสาหกรรมและการใช้งาน

ในการแสวงหาความเป็นเลิศในการผลิตมาสเตอร์แบทช์ จำเป็นต้องคำนึงถึงปัจจัยหลายประการ คุณภาพถือเป็นประเด็นสำคัญ โดยเรียกร้องให้มีการเลือกใช้วัสดุชั้นยอดและปฏิบัติตามมาตรฐานการควบคุมคุณภาพที่เข้มงวด ความรับผิดชอบต่อสิ่งแวดล้อมเน้นย้ำถึงความสำคัญของแนวทางปฏิบัติที่ยั่งยืนและวัสดุที่เป็นมิตรกับสิ่งแวดล้อม เพื่อให้มั่นใจว่าผลิตภัณฑ์ของเรามีผลกระทบต่อสิ่งแวดล้อมน้อยที่สุด

ความแม่นยำในการผลิต ความถูกต้องของสี ความเข้ากันได้ และความคุ้มทุนเป็นองค์ประกอบสำคัญของกระบวนการผลิตที่ประสบความสำเร็จ ความใส่ใจในรายละเอียดในการปฏิบัติตามข้อกำหนดด้านกฎระเบียบทำให้มั่นใจทั้งความปลอดภัยและคุณภาพของผลิตภัณฑ์ สุดท้ายนี้ แนวทางที่ยึดลูกค้าเป็นศูนย์กลางเป็นสิ่งสำคัญยิ่ง โดยไม่เพียงแต่ตอบสนองด้านเทคนิคของการผลิตเท่านั้น แต่ยังรวมไปถึงการส่งมอบและบริการสนับสนุนที่ปรับปรุงประสบการณ์โดยรวมของลูกค้าอีกด้วย

ด้วยการปฏิบัติตามหลักการเหล่านี้ ผู้ผลิตมาสเตอร์แบทช์ไม่เพียงสามารถผลิตผลิตภัณฑ์ที่โดดเด่นเท่านั้น แต่ยังมีส่วนช่วยในอุตสาหกรรมที่ยั่งยืนและคำนึงถึงสิ่งแวดล้อมมากขึ้นอีกด้วย การเดินทางของการผลิตมาสเตอร์แบทช์นั้นซับซ้อนและหลากหลายแง่มุม แต่ด้วยการอุทิศตนเพื่อความเป็นเลิศและการปรับปรุงอย่างต่อเนื่องที่เราปูทางไปสู่นวัตกรรมและความก้าวหน้าในโลกของพลาสติก

เรียนรู้ความรู้และแนวโน้มเพิ่มเติมในอุตสาหกรรมมาสเตอร์แบทช์จากบล็อกของเรา

ในช่วงไม่กี่ครั้งที่ผ่านมา ประสบการณ์ทางประสาทสัมผัสของเรามีอิทธิพลอย่างมากต่อการตัดสินใจของผู้บริโภค ซึ่งส่งผลกระทบอย่างมากต่อยอดขายในอุตสาหกรรมต่างๆ

มาสเตอร์แบตช์อำพันมีบทบาทสำคัญในการพัฒนาและการผลิตบรรจุภัณฑ์ยา โดยเฉพาะวัสดุ PET (โพลีเอทิลีนเทเรฟทาเลต)

ในโลกของพลาสติกที่เปลี่ยนแปลงอยู่ตลอดเวลา มาสเตอร์แบตช์สีขาวมีบทบาทสำคัญในการเพิ่มประสิทธิภาพคุณภาพและประสิทธิภาพของผลิตภัณฑ์พลาสติก บทความนี้จะเจาะลึกถึงความสำคัญของมาสเตอร์แบตช์สีขาว การใช้งาน และผลกระทบต่ออุตสาหกรรมพลาสติก

©2023. ผู้ผลิตมาสเตอร์แบทช์สงวนลิขสิทธิ์

ทีมของเราจะส่งข้อเสนอที่ดีที่สุดใน 20 นาที