- +8615880211820

- [email protected]

- Tongan sanoat parki, Xiamen

| Mahsulot nomi | Yuqori konsentratli Tio2 oq masterbatch |

| Tashqi ko'rinish | Oq granula |

| Tio2 tarkibi | 30% Tio2 / 60% Tio2 / 70% Tio2 / 80% Tio2 |

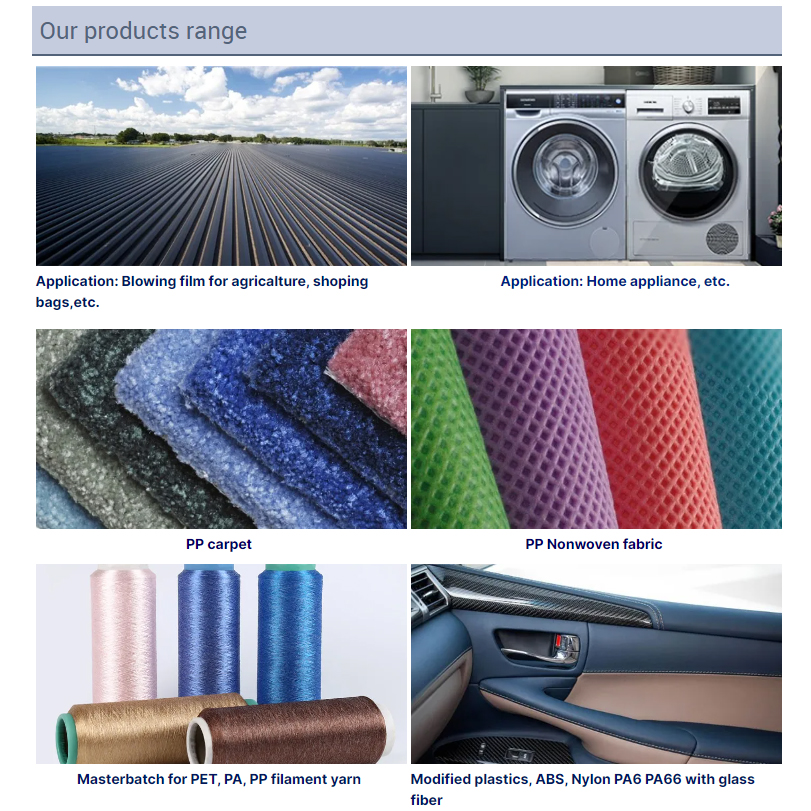

| Ilova | PE plyonkasi, BOPP oq shaffof plyonkasi, yorliqli muzqaymoq qadoqlash, BOPP qattiq oq plyonkasi, yuqori sifatli, to'qilmagan, BOPP plyonkasi |

| Narxlar | Ulgurji narxlar |

| Moslashtirish | Biz mijozning dastur maydoniga muvofiq sozlashni amalga oshirishimiz mumkin. |

| Global agentlar | Biz yetakchilik qilmoqdamiz oq masterbatch ishlab chiqaruvchisi eng katta quvvatga ega, butun dunyo bo'ylab agentlarga ehtiyoj bor |

Oq masterbatch yuqori darajada konsentrlangan aralashma hisoblanadi titan dioksidi (TiO₂) polimer tashuvchisi bilan birgalikda plastik mahsulotlarga toza, yorqin oq ko'rinish va kuchli shaffoflik berish uchun mo'ljallangan. U qadoqlash, qurilish va avtomobilsozlik kabi sohalarda vizual sifat, chidamlilik va ultrabinafsha nurlariga chidamlilikni oshirish uchun keng qo'llaniladi.

Ushbu maqola aniq tushuntirish beradi oq masterbatch, shu jumladan uning tarkibi, ishlab chiqarish jarayoni, qo'llanilishi va ma'lum foydalanish uchun eng mos navni tanlash bo'yicha ko'rsatmalar.

Oq masterbatch o'zining asosiy qismida qatron matritsasi ichida teng ravishda tarqalgan yuqori TiO₂ yuklamasini o'z ichiga olgan plastik qo'shimchadir. Ushbu formula ishlab chiqaruvchilarga erishish imkonini beradi bir xil oqlik, ajoyib shaffoflik va izchil rang yakuniy plastik mahsulot davomida.

Global masterbatch bozori plastik mahsulotlar yanada rivojlangan va dizaynga yo'naltirilgan bo'lib borgan sari o'sishda davom etmoqda. Oq masterbatch ko'p qirrali va samaradorligi tufayli eng ko'p ishlatiladigan turlardan biri bo'lib qolmoqda. Ayniqsa, quyidagilarga talab katta:

• Puflangan plyonkalar va egiluvchan qadoqlash

• Elektronika va maishiy texnika uchun in'ektsion kalıplanmış qismlar

• Ekstruziya plitalari va plastik profillar

• Puflab quyilgan shishalar va idishlar

• Bugungi ishlab chiqaruvchilar ishonchli, tejamkor oq masterbatch izchil natijalarni ta'minlaydi va xalqaro sifat standartlariga javob beradi.

Titan dioksidi (TiO₂): Yuqori yorqinlik, oqlik va qoplama kuchini ta'minlaydigan asosiy pigment.

Tashuvchi qatron: Qayta ishlash jarayonida pigmentni tashiydigan va tarqatadigan asosiy polimer, odatda PE yoki PP.

Funktsional qo'shimchalar: Ishlash va ishlov berish samaradorligini oshiradigan dispersantlar, UV stabilizatorlari va ishlov berish vositalari kabi tarkibiy qismlar.

Yuqori sifatli mahsulot ishlab chiqarish oq masterbatch to'g'ri pigment dispersiyasini va barqaror ishlashni ta'minlash uchun aniq nazorat va ilg'or ishlov berish texnologiyasini talab qiladi.

TiO₂, tashuvchi qatron va qo'shimchalarni aniq dozalash va aralashtirish.

Bir xil dispersiyaga erishish uchun ikki vintli ekstruder orqali yuqori kesish bilan aralashtirish.

Ekstrudatni sovutish va izchil granulalarga kesish.

Ranglarning bir xilligini, dispersiya sifatini va eritma oqimining xususiyatlarini tekshirish uchun qat'iy sinov.

Oq masterbatch keng turdagi plastik mahsulotlarda qo'llaniladi, jumladan:

Qadoqlash: Toza va yuqori sifatli ko'rinishni talab qiladigan plyonkalar, oziq-ovqat idishlari, butilkalar va qopqoqlar.

Qurilish materiallari: Ob-havo va ultrabinafsha nurlariga chidamlilikni talab qiladigan quvurlar, profillar, choyshablar va armaturalar.

Avtomobil komponentlari: Barqaror va izchil rang talab qiladigan ichki plastik qismlar.

Iste'mol mahsulotlari: Uy-ro'zg'or buyumlari, o'yinchoqlar va elektron korpuslar.

Ajoyib shaffoflik: Yorqin, bir xil oq rang hosil qiladi.

UV qarshilik: TiO₂ ultrabinafsha nurlanishini blokirovka qilishga yordam beradi va mahsulotning ishlash muddatini uzaytiradi.

Iqtisodiy samaradorlik: To'g'ridan-to'g'ri kukun aralashtirish bilan solishtirganda pigmentdan samaraliroq foydalanish.

Kengaytirilgan ishlov berish: Ishlab chiqarish jarayonida material oqimini va pigment dispersiyasini yaxshilaydi.

TiO₂ tarkibi: Yuqori pigment darajasi shaffoflikni oshiradi, ammo narxga ham ta'sir qiladi.

Tashuvchi qatronlar mosligi: Tashuvchi asosiy plastik qatron bilan mos kelishi kerak.

Termal barqarorlik: Formulatsiya ishlatiladigan ishlov berish haroratiga bardosh berishi kerak.

Yakuniy foydalanish talablari: Tashqi makon uchun odatda qo'shimcha UV himoyasi talab qilinadi.

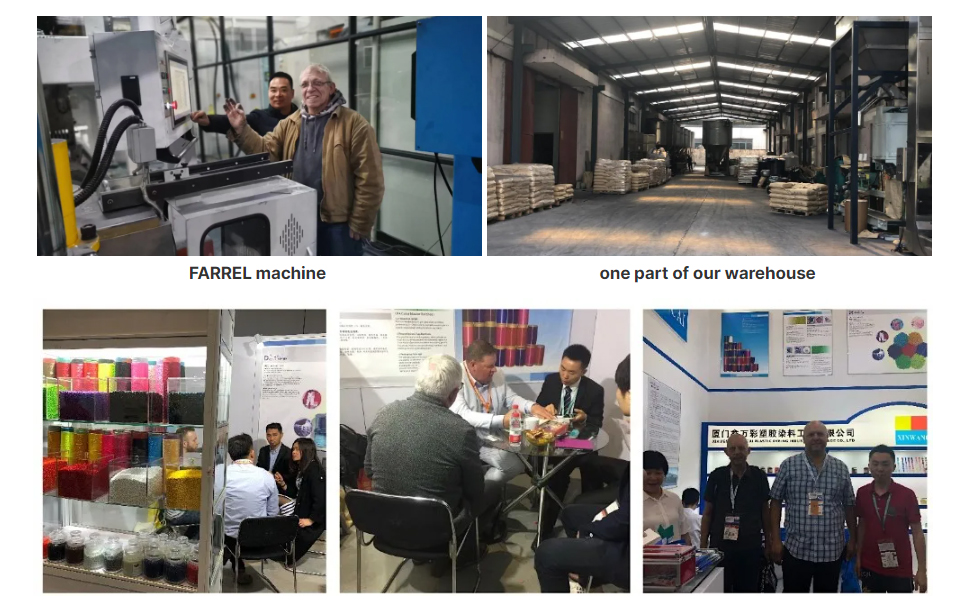

Bizning Masterbatch masterbatch sanoatida ishonchli va tajribali ishlab chiqaruvchi hisoblanadi. Germaniyadan import qilingan va pigment dispersiyasi bo'yicha o'nlab yillik tajribaga ega bo'lgan ilg'or ikki vintli ekstruziya tizimlari bilan jihozlangan kompaniya barqaror, yuqori samarali rangli va funktsional masterbatch yechimlarini taqdim etadi. Bizning Masterbatch quyidagilarni o'z ichiga oladi:

Antistatik Masterbatch

Bizning Masterbatch mahsulotimiz Yevropa, Janubiy Amerika, Janubi-Sharqiy Osiyo, Yaqin Sharq va Shimoliy Afrika bo'ylab 45 dan ortiq mamlakatlarga eksport qilinadi. Kompaniya mijozlarning muvaffaqiyatini qo'llab-quvvatlash uchun keng qamrovli texnik yordam va moslashtirilgan formulalarni taklif etadi.

Bizning kompaniyamiz 20 yildan ortiq plastik masterbatch sanoatida ishlaydi, biz Xitoyning Xiamen shahridagi Tong'an sanoat parkida joylashgan Rangli masterbatch, funktsional masterbatch, shisha tolali mustahkamlangan plastmassa va yonishga chidamli plastik xom ashyoni tadqiq qilish va ishlab chiqarishga ixtisoslashganmiz.

Xulosa qilib aytganda, biz plastik masterbatchning barcha turlarini ishlab chiqarishda professionalmiz, jumladan qo'shimchali masterbatch, funktsional masterbatch, pe olovga chidamli masterbatch, ABS olovga chidamli masterbatch, anti-kislorod masterbatch, anti-UV masterbatch, antibakterial masterbatch, antiblock masterbatch , va ba'zi boshqa qo'shimchalar masterbatches.

Bizning masterbatchlarimiz turli sohalarda ko'plab ilovalarni topadi. Plastmassa, to'qimachilik yoki turli ishlab chiqarish jarayonlarida bo'ladimi, bizning masterbatchlarimiz mahsulot sifati va samaradorligini oshirishda muhim rol o'ynaydi. Sozlanishi mumkin bo'lgan formulalar bilan ular ranglarning mustahkamligi, UV himoyasi, olovga chidamliligi va boshqalarni taklif qiladi, bu ularni son-sanoqsiz ilovalar uchun asosiy yechimga aylantiradi. Avtomobil qismlaridan qadoqlash materiallarigacha, bizning masterbatchlarimiz sanoatning keng spektrida yuqori natijalarga erishish uchun ishonchli tanlovdir.

Bizning maxsus masterbatchlarimiz tanlangan materialga kiritilganda optimal ishlashni ta'minlaydigan maxsus polimerlarga mos ravishda ishlab chiqilgan. Biz quyida aytib o'tilgan turli xil polimerlar uchun mos bo'lgan masterbatchlarni ishlab chiqarish imkoniyatiga egamiz va yana ko'p. Agar siz bu erda ro'yxatda bo'lmagan material bilan ishlayotgan bo'lsangiz, iltimos, maxsus ehtiyojlaringizni qondirish imkoniyatini o'rganish uchun bilimdon texnik guruhimizga murojaat qilishdan tortinmang.

Past zichlikdagi polietilen - HDPE dan biroz shaffofroq va sezilarli darajada egiluvchan, asosan moslashuvchan qadoqlash, sumkalar, egiluvchan quvurlar, plyonkalar va shunga o'xshash maqsadlarda qo'llaniladi. HDPE singari, u cheklangan shaffoflik xususiyatlariga ega. U spirtlar, kislotalar va ishqorlarga nisbatan ajoyib kimyoviy qarshilik ko'rsatadi, ammo uglevodorod erituvchilar va mineral moylarga nisbatan cheklangan qarshilikka ega. UV nurlanishiga uzoq vaqt ta'sir qilish degradatsiyani boshlashi mumkin.

Yuqori zichlikdagi polietilen - Bir oz sutli-oq ko'rinishga ega bo'lgan ushbu material qattiq shisha qadoqlash, in'ektsiya bilan qoplangan qopqoq va qopqoqlar, qutilar va boshqalarda keng qo'llaniladi. Uning tabiiy shaffofligi erishish mumkin bo'lgan shaffoflik darajasini cheklashi mumkin. HDPE LDPE bilan solishtirganda yuqori kimyoviy va erituvchiga qarshilik ko'rsatadi.

PPCO Random & PPHO - O'rtacha tiniqlikka ega bo'lgan polimer, qopqoq va yopish ishlab chiqarishda qo'llaniladi. Bundan tashqari, u uy-ro'zg'or buyumlari, chelaklar, o'yinchoqlar va saqlash idishlarini tayyorlash uchun ishlatiladi. Polipropilen rang yoki maxsus effektlarda sezilarli cheklovlarsiz moslashuvchanlikni ta'minlaydi. Tasodifiy sopolimer gomopolimerga nisbatan ko'proq tiniqlikka ega va shaffof soyalarni yaratish uchun ko'proq mos keladi.

PPCO bloki - PPCO ga o'xshash, ammo zarba qarshiligini oshirish uchun yaxshilangan. Qo'shimcha polimerni oq rangga aylantiradi, bu esa yuqori shaffoflikka olib keladi. Bu xususiyat erishiladigan shaffoflikni cheklashi mumkin.

Polietilen tereftalat (PET) - Polyester materiallari mukammal kimyoviy qarshilik va to'siq xususiyatlari bilan birga mustahkam mexanik kuchga ega. Gazlangan ichimliklar idishlarini ishlab chiqarish uchun PET tez-tez tanlanadi. Bundan tashqari, polyester yigirilib, kiyim-kechak uchun to'qimachilik ishlab chiqarishda ishlatilishi mumkin. PET juda shaffof bo'lib, uni shaffof qadoqlash uchun ajoyib tanlov qiladi, garchi "sarg'ish" ning nozik ishorasi juda ochiq ranglarga ta'sir qilishi mumkin.

Polibutilen tereftalat - elektronika sohasida izolyatsion material sifatida tez-tez ishlatiladigan kristalli termoplastik muhandislik polimeri. Ushbu modda poliester toifasiga tegishli bo'lib, atributlar va ishlov berish sifatining ajoyib muvozanatini namoyish etadi.

Umumiy maqsadli polistirol - shishadek tiniq ko'rinishga ega, ammo minimal zarba qarshiligiga ega bo'lgan ushbu material CD qutilarida asosiy qo'llanilishini topadi. Uning sezilarli tiniqligi uni shaffof ranglar yaratish uchun mos qiladi, garchi vaqti-vaqti bilan binafsha rangni sezish mumkin.

Yuqori ta'sirli polistirol - zarbalarga chidamliligini oshirish uchun ta'sirni kuchaytiruvchi vositani o'z ichiga olgan GPPSdan olingan. Ushbu qo'shilgan komponent polimerning oq rangga aylanishiga olib keladi va turli formulalar turli darajadagi shaffoflikni ta'minlaydi. Odatda o'yin qismlari, o'yinchoqlar va shunga o'xshash narsalarni ishlab chiqarishda qo'llaniladi. Uning aniq oqligi shaffof rang berishni maqsad qilganda qiyinchiliklarga olib kelishi mumkin. GPPS bilan bir xil shaffoflik darajasiga erishish uchun K-Resin va Styrolux kabi ixtisoslashtirilgan alternativalar bozorda mavjud.

Akrilonitril butadien stirol (ABS) - Yuqori ta'sirli polistirolning (HIPS) yanada mustahkam iteratsiyasi yuqori qiymatli komponentlarda qo'llaniladi. ABS HIPS tomonidan ishlab chiqarilgan komponentlarga nisbatan ancha chidamliligini namoyish etadi, garchi u shaffof ranglarga erishishga urinayotganda shunga o'xshash qiyinchiliklarga duch keladi. Xuddi HIPS singari, ABS ham maxsus shaffof variantlarni taklif etadi. Chidamliligi tufayli ABS odatda elektr asboblari uchun korpuslarni tayyorlashda qo'llaniladi.

Poliamid (6, 66) - Neylon mexanik qurilish va texnik xizmat ko'rsatishda keng qo'llaniladigan ko'p qirrali sinfdir. Uning mashhurligi mexanik kuch, qattiqlik, mexanik damping xususiyatlari va samarali elektr izolyatsiyasi imkoniyatlarining ajoyib aralashmasidan kelib chiqadi. Shunday qilib, neylon elektr korpuslarini ishlab chiqarish uchun afzal qilingan materialdir. PA66 kimyoviy va fizik atributlari PA6 ga juda o'xshash bo'lgan turli xil ilovalarda metallga umumiy muqobil bo'lib xizmat qiladi. PA6 namlikni yutish uchun yuqori sezuvchanlikka ega bo'lsa-da, yuqori zarba qarshiligi va erituvchilarga qarshilik ko'rsatadi.

Stirol akrilonitril kopolimeri - Shaffoflik va ajoyib kimyoviy va issiqlik qarshiligiga ega, SAN shuningdek, yaxshi qattiqlik, valentlik va egilish kuchiga ega. Yuqori porloq qoplamasi tufayli SAN odatda kosmetik qadoqlash uchun tanlanadi. Biroq, SAN yordamida ochiq rangdagi ranglarga erishish, ishlab chiqarish jarayonida uning vizual ko'rinishini yaxshilash uchun ishlatiladigan materialga xos bo'lgan binafsha rang bo'yoqlari tufayli qiyin bo'lishi mumkin.

Polietilen tereftalat glikol - glikolni o'z ichiga olgan PET. Ushbu glikol qo'shilishi oqim xususiyatlarini yaxshilaydi, lekin kuchini pasaytiradi. PETG shishalarni yaratish uchun ekstrudirovka qilinishi mumkin va "blister" uslubidagi qadoqlash uchun choyshablarga aylantirilishi mumkin.

Termoplastik elastomer (TPE) yoki termoplastik poliuretan (TPU) - TPU avtomobil asboblar paneli, g'ildirak g'ildiraklari, elektr asboblari, tibbiy asboblar, shuningdek, turli xil ekstrudirovka qilingan plyonka, qatlam va profil ilovalari kabi ilovalarda turli xil foydalanishni topadi. TPElar avtomobilsozlik, tibbiyot, qurilish, elektrotexnika, maishiy texnika, qadoqlash va sanoat sohalarida keng ko'lamli dasturlarda qo'llaniladi.

Bizning masterbatchimiz haqida tez-tez so'raladigan savollar

©2023. Masterbatch ishlab chiqaruvchisi barcha huquqlar himoyalangan.

Bizning jamoamiz 20 daqiqada eng yaxshi taklifni qaytaradi.