Galogensiz olovga chidamli Masterbatch nima?

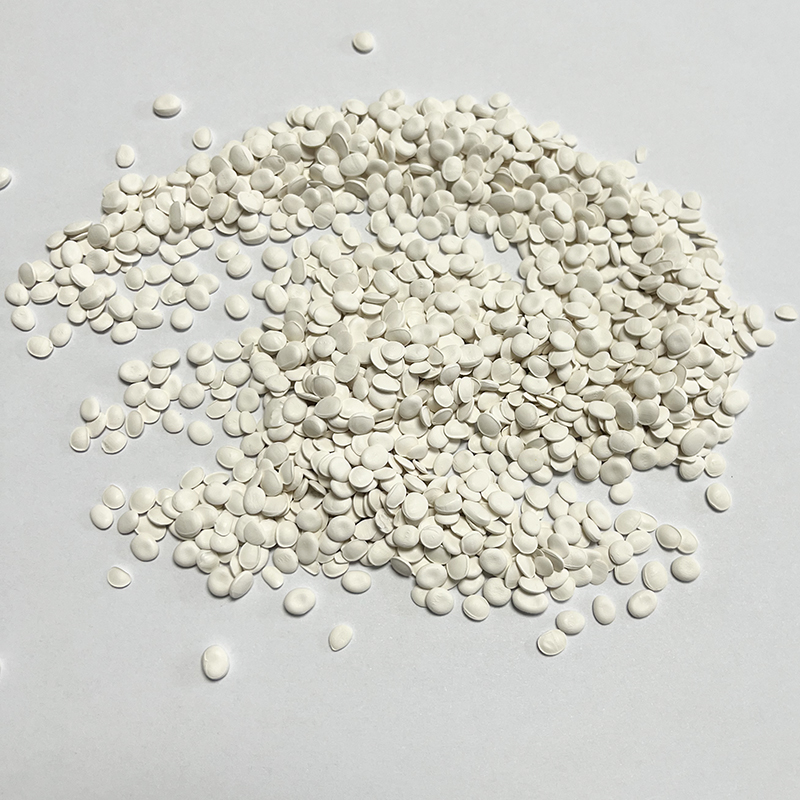

Galogensiz olovga chidamli Masterbatch - bu halogensiz olovga chidamli Masterbatch. Uni plyonka, karton va boshqa plastmassa buyumlarga qayta ishlash mumkin. Olovga chidamli Masterbatch kuchli dispersiyaga, a'lo mexanik xususiyatlarga ega va ekologik toza.