What Is Masterbatch and How Is It Used?

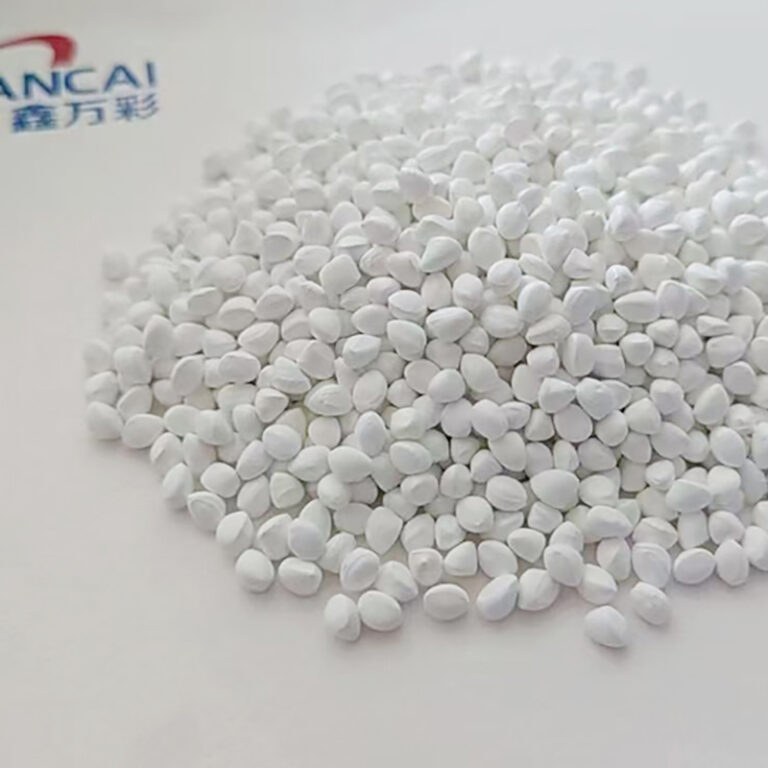

Masterbatch refers to a solid additive used in the plastics industry to enhance properties or impart color to polymers. Essentially, it is a highly concentrated mixture of pigments or additives dispersed within a polymer carrier. This mixture is subjected to heat and high-shear mixing in an extruder, then cooled, cut, and transformed into granules or pellets through a pelletizer.