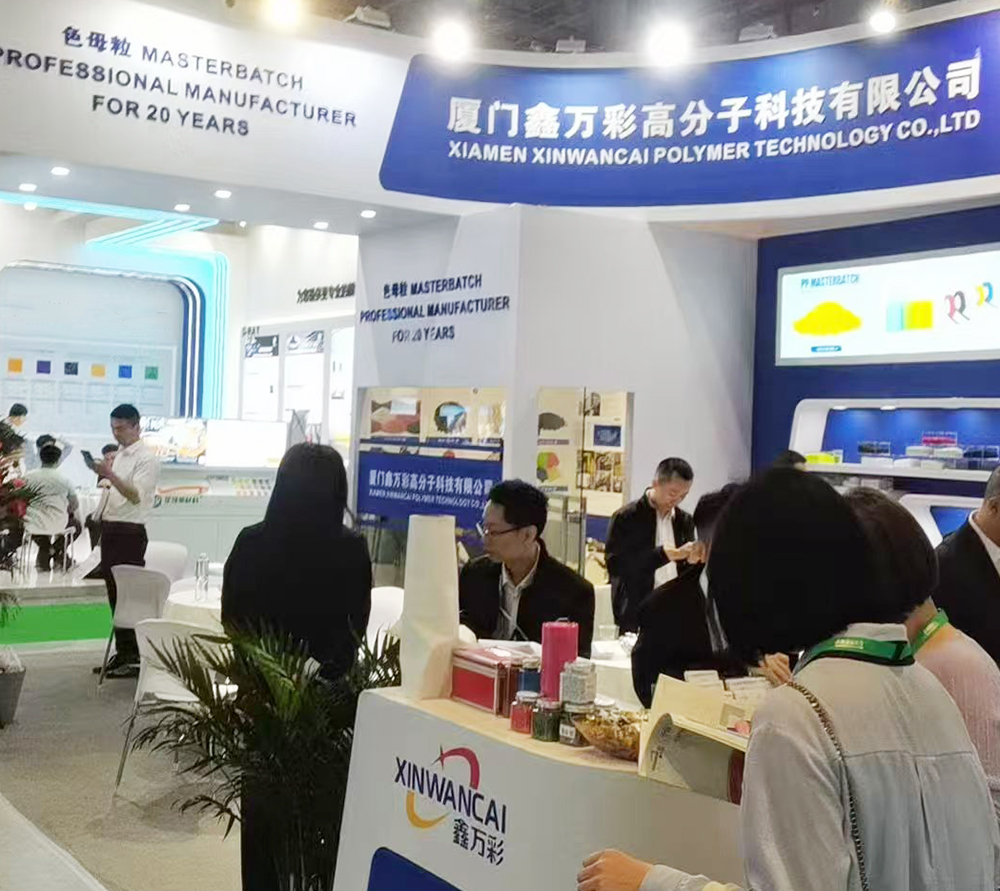

Top White Masterbatch Manufacturer in China – Xiamen Xinwancai Masterbatch

Xiamen Xinwancai Masterbatch is recognized as one of the leading suppliers of high-quality white masterbatch in China, offering premium PE white masterbatch suitable for applications in film production, packaging, and agricultural mulch films, all at competitive prices.