The Crucial Role of Electret Masterbatch in Enhancing Meltblown Cloth Filtration Efficiency

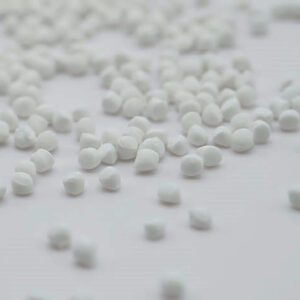

Electret masterbatch is a specially formulated additive that significantly enhances the filtration efficiency of meltblown fabrics by enabling them to capture fine particles through an electrostatic charge.