- +8615880211820

- [email protected]

- No.67, Tongan Industry Park, Xiamen

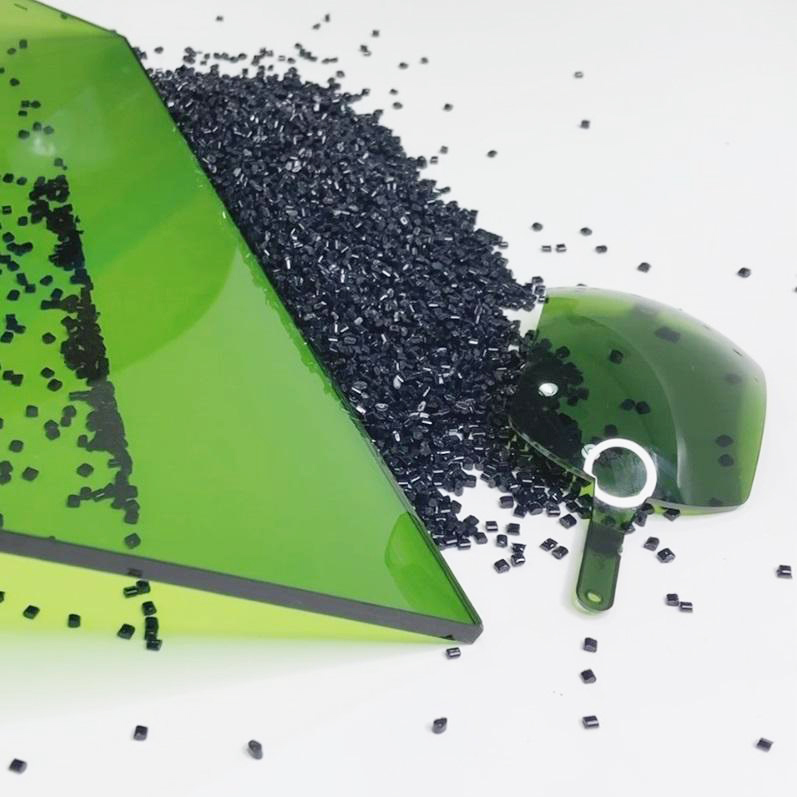

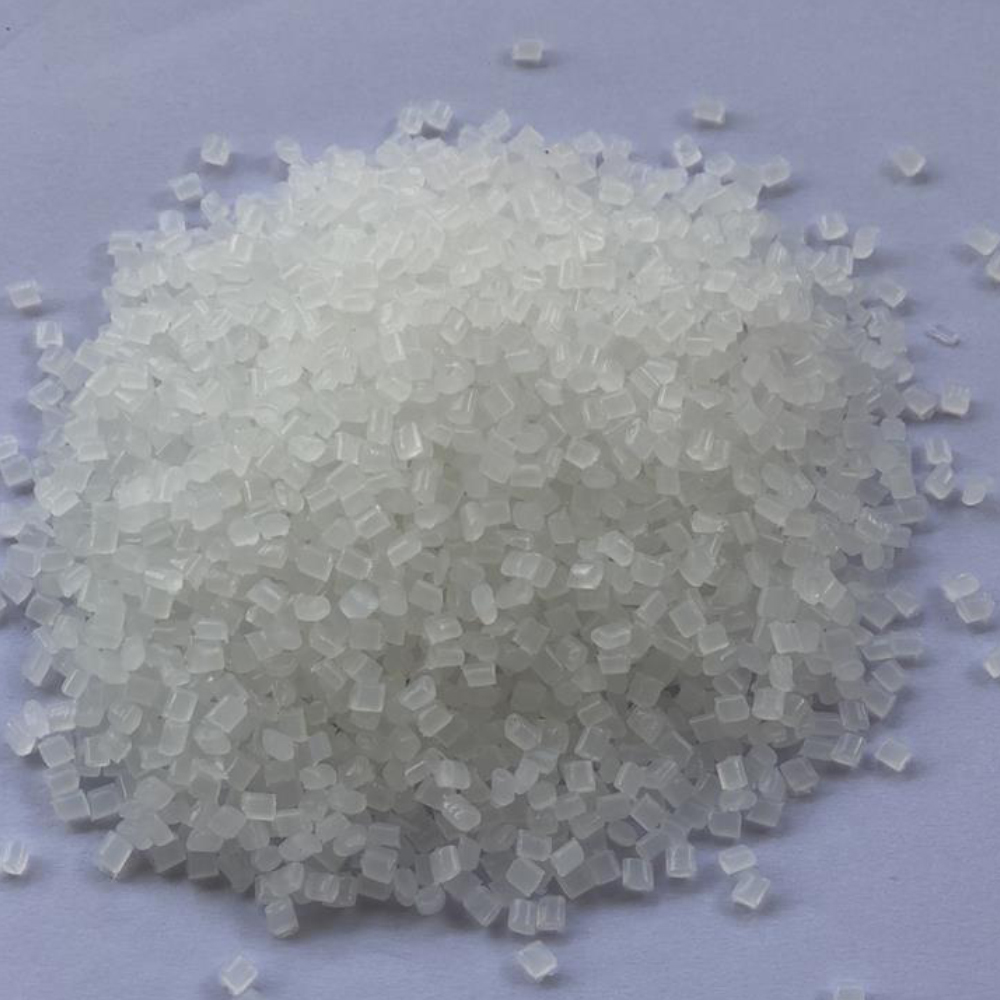

In today’s ever-evolving world of plastics, ensuring the longevity and resilience of your polymer-based products is paramount. With the ever-present threat of UV radiation, discolouration, and mechanical property degradation, manufacturers must invest in UV stabilizer masterbatches that can safeguard their creations. In this article, we introduce you to a reliable UV masterbatch stabilizer manufacturer that offers wholesale solutions tailored to your needs.

UV Masterbatches play a vital role in the realm of plastics by protecting them against the detrimental effects of UV radiation. These remarkable additives not only prevent discolouration but also enhance processibility, ensuring that your products maintain their pristine appearance and quality. What makes UV Stabilizer Masterbatches truly exceptional is their ability to block harmful UV rays while stabilizing mechanical properties and elongation. This, in turn, guards against issues such as crazing and chalking.

One of the many merits of UV Masterbatches is their versatility. These stabilizers are perfect for a wide range of applications, including jumbo bags, irrigation films, and rotomoulding items. The resilience they impart to plastics extends their usability in various fields. Whether it’s outdoor furniture, automotive components, or agricultural equipment, the use of UV Masterbatches ensures that your products can withstand the test of time, even in the face of adverse conditions.

The importance of UV Masterbatches goes beyond their aesthetic advantages. Long-term exposure to sunlight can trigger chemical reactions that degrade the structure of plastic products. UV Masterbatches act as guardians of durability, minimizing this degradation process and maintaining the structural integrity of your creations. This means that your products remain robust and stable over an extended period, irrespective of environmental exposure.

Constant exposure to sunlight often leads to fading of colors in plastic products. The application of UV Masterbatches prevents this undesirable effect, ensuring that your products retain their vibrant appearance day after day. Your plastic creations will look and stay as fresh as they did on day one, even in the harshest of sunlight.

Another remarkable attribute of UV Masterbatches is their chemical resistance. When exposed to various chemicals and other degrading components, common plastic products often disintegrate rapidly. However, with the addition of UV Masterbatches, your products gain added strength and resistance, making them more robust and durable. This is particularly valuable in applications where exposure to chemicals is a constant concern.

UV Masterbatches serve a dual purpose by absorbing harmful UV radiation. Not only do they preserve the integrity of plastic structures, but they also safeguard the contents within. This extra layer of protection ensures that whatever is housed within the plastic structure remains safe for an extended duration.

In conclusion, UV Masterbatches are a game-changer for the plastic manufacturing industry. They not only enhance the aesthetic appeal of products but also extend their lifespan and ensure their durability in challenging conditions. If you’re looking for a dependable UV masterbatch stabilizer manufacturer for your wholesale needs, consider the one highlighted in this article. Their commitment to excellence ensures that your plastic creations will stand the test of time, shining under the sun’s rays for years to come.

Our masterbatches find a multitude of applications across diverse industries. Whether in plastics, textiles, or various manufacturing processes, our masterbatches play a pivotal role in enhancing product quality and performance. With customizable formulations, they offer color consistency, UV protection, flame resistance, and more, making them the go-to solution for countless applications. From automotive parts to packaging materials, our masterbatches are the trusted choice for achieving superior results across a wide spectrum of industries.

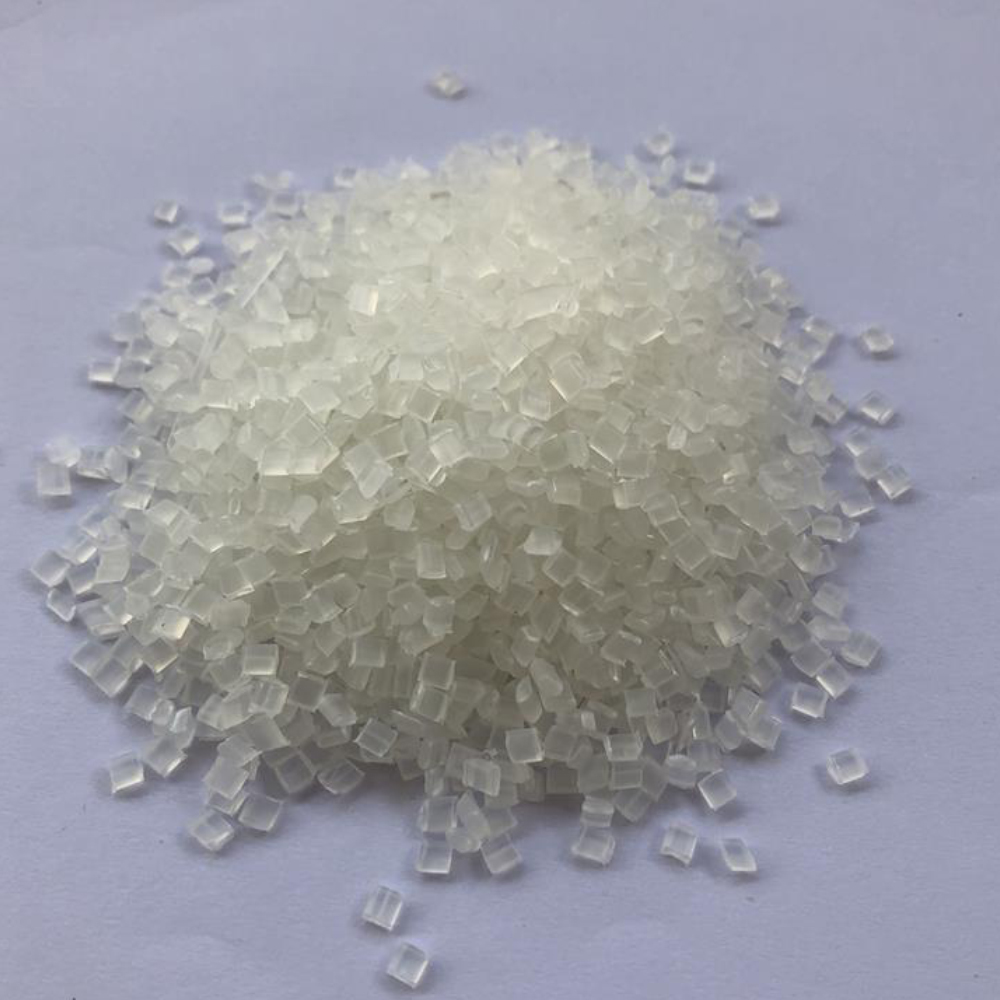

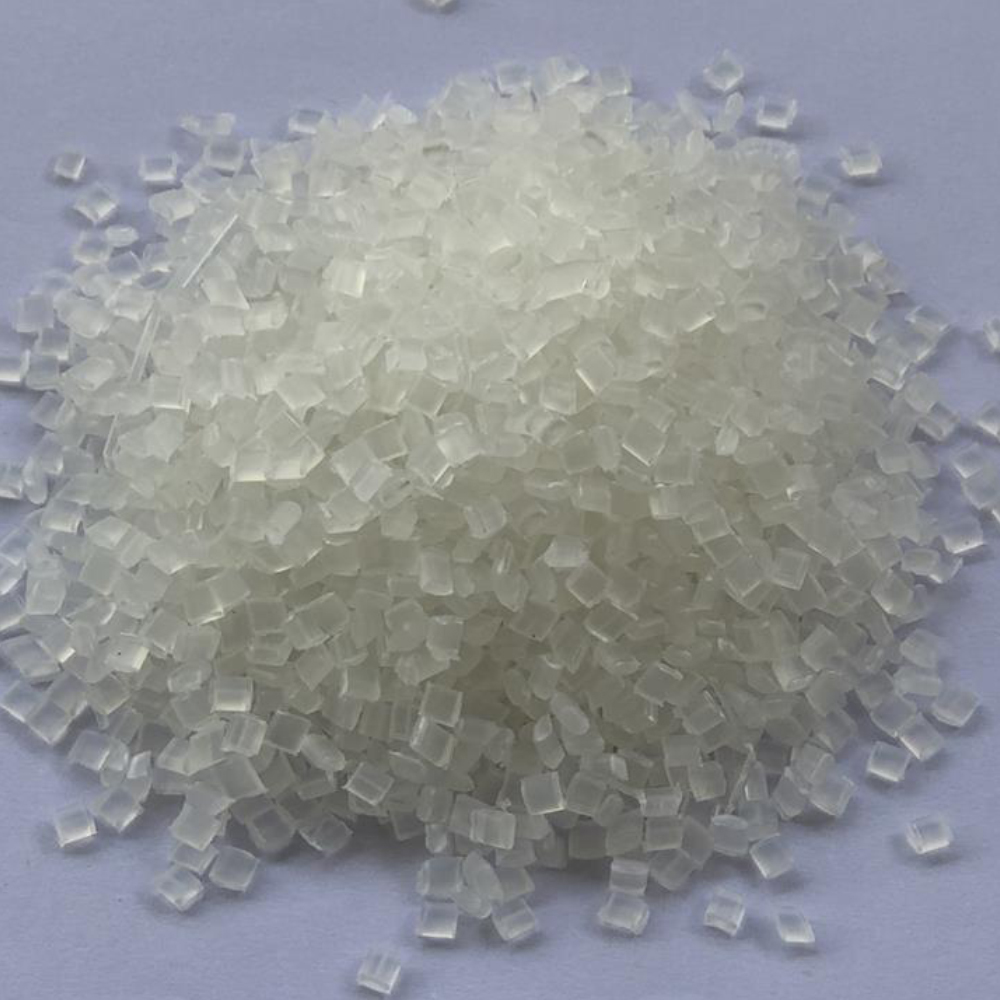

Our custom masterbatches are designed to match specific polymers, ensuring optimal performance when incorporated into your selected material. We have the capability to produce masterbatches suitable for a variety of polymers mentioned below, and many more. If you’re working with a material that isn’t listed here, please don’t hesitate to reach out to our knowledgeable technical team to explore the possibility of meeting your specific needs.

Low Density Polyethylene – Somewhat more translucent than HDPE and considerably more pliable, primarily employed in flexible packaging, tote bags, pliable tubing, film applications, and similar uses. Like HDPE, it has limited transparency characteristics. It exhibits outstanding chemical resistance to alcohols, acids, and alkalis but has restricted resistance to hydrocarbon solvents and mineral oils. Prolonged exposure to UV radiation can initiate degradation.

High-Density Polyethylene – Featuring a somewhat milky-white appearance, this material finds wide application in rigid bottle packaging, injection-molded caps and closures, crates, and more. Its natural opacity can limit the degree of transparency attainable. HDPE exhibits superior chemical and solvent resistance when compared to LDPE.

PPCO Random & PPHO – A polymer with moderate clarity, employed in the production of caps and closures. It is also utilized for crafting household items, buckets, toys, and storage containers. Polypropylene offers flexibility without significant limitations on color or special effects. Random copolymer boasts greater clarity compared to homopolymer and is better suited for creating translucent shades.

PPCO Block – Similar to PPCO but enhanced for increased impact resistance. An additive renders the polymer white, resulting in high opacity. This characteristic may limit the achievable transparency.

Polyethylene Terephthalate (PET) – Polyester materials exhibit robust mechanical strength along with excellent chemical resistance and barrier properties. PET is frequently chosen for the production of carbonated beverage containers. Moreover, polyester can be spun and employed in textile manufacturing for clothing. PET is highly transparent, making it an excellent choice for translucent packaging, although a subtle hint of “yellowing” may impact extremely light tints.

Polybutylene Terephthalate – A crystalline thermoplastic engineering polymer frequently employed as an insulating material within the electronics sector. This substance belongs to the polyester category, showcasing a remarkable equilibrium of attributes and processing qualities.

General Purpose Polystyrene – Exhibiting a glass-clear appearance but possessing minimal impact resistance, this material finds its primary application in CD cases. Its notable clarity renders it suitable for creating translucent hues, although an occasional violet tint may be discernible.

High Impact Polystyrene – Derived from GPPS by incorporating an impact-enhancing agent to boost its resistance to impacts. This added component results in the polymer becoming white, and different formulations provide varying degrees of opacity. Typically employed in the fabrication of game pieces, toys, and similar items. Its pronounced whiteness can pose challenges when aiming for translucent coloration. Specialized alternatives like K-Resin and Styrolux are accessible in the market to attain the same level of translucency as GPPS.

Acrylonitrile Butadiene Styrene (ABS) – A more robust iteration of High Impact Polystyrene (HIPS) employed in high-value components. ABS exhibits greater durability compared to HIPS-made components, although it encounters similar challenges when attempting to achieve translucent colorations. Just like HIPS, ABS offers specialized translucent variants. Owing to its durability, ABS is commonly used in crafting casings for power tools.

Polyamide (6, 66) – Nylon represents a versatile grade extensively employed in mechanical construction and maintenance. Its popularity stems from its excellent blend of mechanical strength, rigidity, mechanical damping characteristics, and effective electrical insulation capabilities. Consequently, nylon is a preferred material for manufacturing electrical enclosures. PA66 serves as a common alternative to metal across diverse applications, with its chemical and physical attributes closely resembling those of PA6. PA6 exhibits superior impact resistance and resistance to solvents, albeit with a heightened susceptibility to moisture absorption.

Styrene Acrylonitrile Copolymer – Possessing transparency and outstanding chemical and heat resistance, SAN also boasts good rigidity, tensile strength, and flexural strength. Thanks to its high-gloss finish, SAN is commonly chosen for cosmetic packaging purposes. However, achieving light tint colors with SAN can be challenging due to the violet dyestuffs inherent in the material, which are utilized to enhance its visual appearance during manufacturing.

Polyethylene Terephthalate Glycol – PET with the incorporation of glycol. This glycol addition enhances flow properties but diminishes strength. PETG can be extruded to create bottles and can be formed into sheets for producing ‘blister’ style packaging.

Thermoplastic Elastomer (TPE) or Thermoplastic Polyurethane (TPU) – TPU finds diverse uses in applications such as automotive instrument panels, caster wheels, power tools, medical devices, as well as various extruded film, sheet, and profile applications. TPEs are employed across a wide range of applications in industries spanning automotive, medical, construction, electrical, appliances, packaging, and industrial sectors.

Frequently asked questions about our masterbatch

©2023. Masterbatch Manufacturer All Rights Reserved.

Our team will send back the best offer in 20 minutes.