Enhancing Daily Life Through Masterbatches in the Packaging Industry

The packaging industry, a diverse sector employing advanced technology and allied resources, serves the crucial role of enclosing products for storage, transportation, and sale.

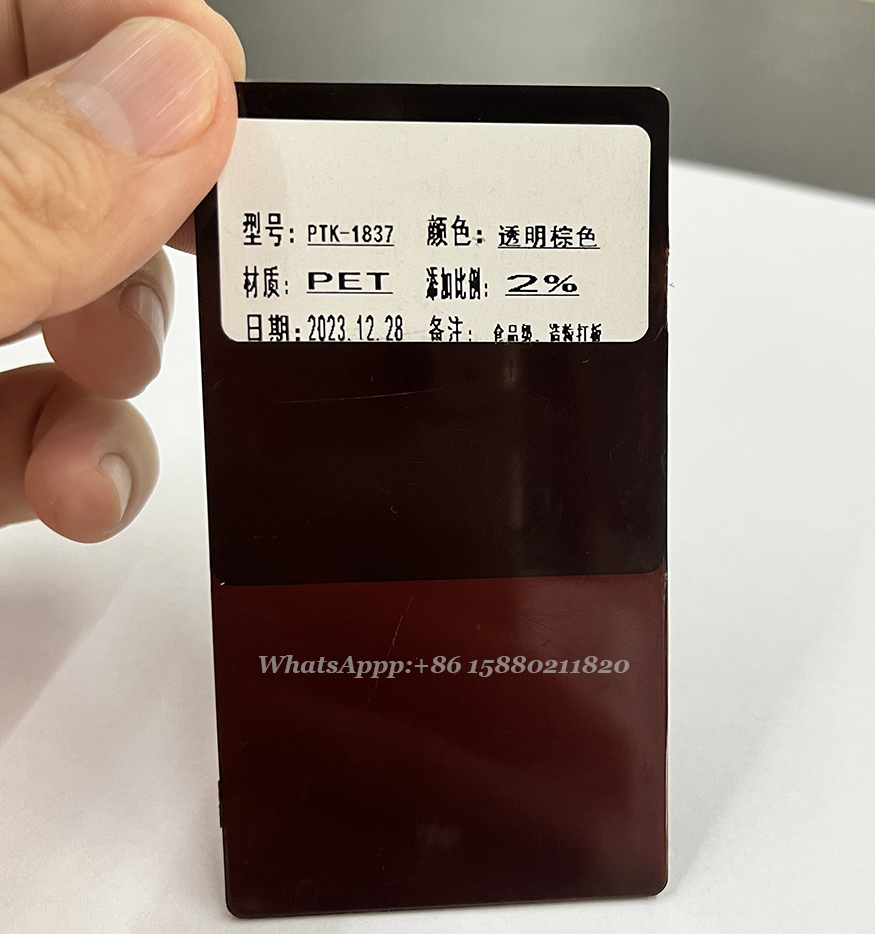

PET masterbatches are concentrated pigment, additive, and polymer mixtures added to PET for improved color, strength, and processing. Ideal for PET bottles and films, they offer high-quality base polymer stability and a wide range of vibrant colors. PET masterbatches are characterized by their color consistency, UV stability, and processing stability, making them suitable for high-demand applications.

PET White Masterbatches: Bright, opaque white.

PET Color Masterbatches: Various vibrant colors, including Amber masterbatch, Blue masterbatch, and Orange masterbatch.

PET Carbon Black Masterbatches: Deep black with enhanced UV resistance.

PET Film Resin Masterbatch: For film applications with excellent optical properties.

Each type offers unique advantages, such as UV resistance in PET carbon black masterbatches and a bright base in PET white masterbatches. Selecting the right masterbatch ensures optimal results in plastic manufacturing.

With Iplastar’s PET masterbatches, industries can achieve superior color quality, cost efficiency, and production effectiveness. Explore the benefits of Iplastar’s high-quality PET masterbatches and elevate your plastic manufacturing processes. For more details and to request a quote, visit masterbatch manufacturer.

Learn more knowledge and trends in masterbatch industry from our blog.

The packaging industry, a diverse sector employing advanced technology and allied resources, serves the crucial role of enclosing products for storage, transportation, and sale.

In recent times, our sensory experiences have gained prominence in influencing consumer choices, significantly impacting sales across various industries.

The field of plastics manufacturing is continually advancing, driven by innovations in materials and processes that cater to diverse industry needs. One such breakthrough is the use of masterbatch, a solid additive that has become essential in polymer processing.

©2023. Masterbatch Manufacturer All Rights Reserved.

Our team will send back the best offer in 20 minutes.