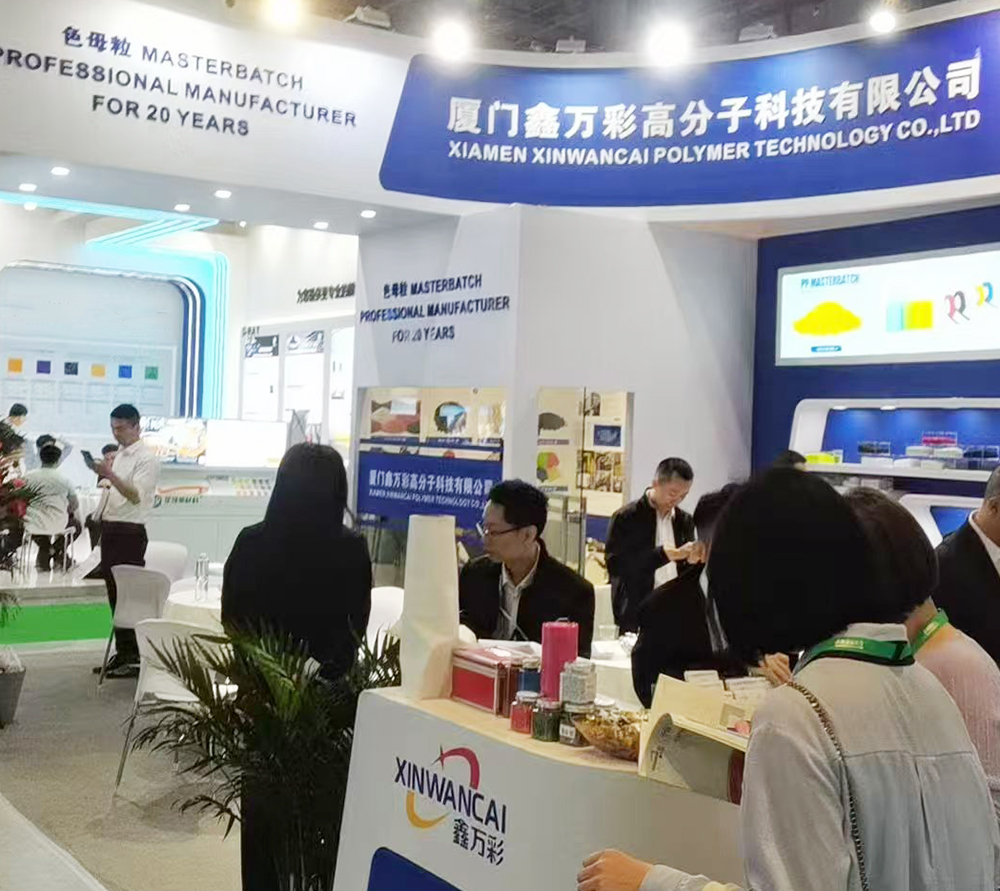

Fabricante líder de masterbatch blanco en China: Xiamen Xinwancai Masterbatch

Xiamen Xinwancai Masterbatch es reconocido como uno de los principales proveedores de masterbatch blanco de alta calidad en China, y ofrece masterbatch blanco de PE de primera calidad adecuado para aplicaciones en producción de películas, embalaje y películas de mantillo agrícola, todo a precios competitivos.