Aplikasi Masterbatch: Meneroka Pelbagai Industri

Bagi perniagaan yang beroperasi dalam sektor seperti pembungkusan, automotif, barangan pengguna, pembinaan atau tekstil, kebiasaan dengan Masterbatch berkemungkinan penting dalam proses pembuatan.

Langkah utama termasuk memilih bahan mentah berkualiti tinggi seperti pigmen karbon hitam, resin pembawa dan bahan tambahan. Bahan-bahan ini dicampur dan dikompaun dalam penyemperit skru berkembar, di mana ia mengalami peleburan, pencampuran dan penyahgas untuk memastikan penyebaran seragam dan mengeluarkan komponen yang tidak menentu. Bahan lebur kemudiannya dipelet menjadi panjang seragam dan tertakluk kepada ujian kawalan kualiti yang ketat. Proses ini memastikan pengeluaran masterbatch berkualiti tinggi, yang penting untuk mencipta produk plastik berwarna hitam dengan estetika, fungsi dan prestasi yang dipertingkat, digunakan secara meluas dalam industri plastik.

Penghasilan masterbatch warna masterbatch hitam cair adalah proses yang teliti yang menggabungkan pelbagai komponen untuk mencapai kualiti warna dan penyebaran yang dikehendaki. Proses ini lazimnya melibatkan penggunaan penyemperit skru berkembar atau jentera pengkompaun yang serupa untuk mencampur, menyuraikan dan mempelt bahan masterbatch dengan berkesan. Di sini, kami memperincikan langkah-langkah utama dalam proses pembuatan masterbatch warna masterbatch hitam cair.

Langkah awal melibatkan pemilihan bahan mentah berkualiti tinggi, termasuk pigmen, resin pembawa, dan bahan tambahan. Karbon hitam adalah pigmen pilihan untuk warna hitam yang unggul, rintangan UV, dan kestabilan terma. Resin pembawa seperti polietilena (PE) atau polipropilena (PP) dipilih berdasarkan keserasiannya dengan matriks polimer produk akhir. Bahan tambahan seperti agen penyerakan, bantuan pemprosesan dan penstabil juga boleh dimasukkan untuk meningkatkan ciri-ciri penyebaran dan pemprosesan.

Selepas memilih bahan mentah, ia ditimbang dengan tepat dan diadun mengikut formulasi yang dikehendaki. Pigmen, resin pembawa, dan bahan tambahan dimasukkan ke dalam corong penyemperit skru berkembar dalam perkadaran yang tepat. Di dalam penyemperit, bahan mengalami tenaga mekanikal dan haba yang sengit semasa ia bergerak di sepanjang skru.

Apabila bahan maju melalui penyemperit, mereka terdedah kepada peningkatan suhu dan tekanan. Skru di dalam penyemperit memberikan daya ricih mekanikal dan tindakan pencampuran pengagihan, memastikan penyebaran pigmen yang menyeluruh dalam resin pembawa. Gabungan haba dan daya ricih mencairkan resin, membolehkan pigmen merebak secara sama rata ke seluruh matriks polimer.

Semasa pengkompaunan, komponen yang tidak menentu seperti lembapan dan udara boleh terperangkap dalam leburan. Untuk menghapuskan gas-gas ini dan memastikan keseragaman, leburan mengalami peringkat penyahgas, biasanya menggunakan bolong vakum atau zon penyahgas dalam tong penyemperit. Degassing membantu mencegah kecacatan permukaan dan memastikan kualiti produk akhir.

Setelah rumusan masterbatch dihomogenkan dan dinyahgas, ia diekstrusi melalui acuan untuk membentuk untaian bahan cair yang berterusan. Helaian ini kemudiannya disejukkan dan dipadatkan dengan cepat menggunakan air atau udara, menghasilkan pelet silinder. Pelet dipotong mengikut panjang seragam menggunakan peralatan pelletizing.

Sepanjang proses pembuatan, langkah kawalan kualiti yang ketat dilaksanakan untuk memastikan konsistensi dan pematuhan kepada spesifikasi. Sampel masterbatch diuji untuk keamatan warna, serakan, sifat aliran cair, kestabilan terma dan parameter prestasi lain. Sebarang penyimpangan daripada spesifikasi yang diingini akan ditangani dengan segera untuk mengekalkan kualiti produk.

Pengilangan masterbatch warna masterbatch hitam cair adalah operasi yang kompleks dan tepat yang memerlukan kepakaran dan kawalan kualiti yang ketat. Dengan menggabungkan pigmen, resin pembawa, dan bahan tambahan dengan penyemperit skru berkembar, pengeluar mencapai penyebaran seragam dan konsistensi warna dalam produk akhir. Masterbatch ini ialah bahan tambahan penting dalam industri plastik, membolehkan pengeluaran produk plastik berwarna hitam dengan ciri estetika, fungsi dan prestasi yang dipertingkatkan.

Ketahui lebih banyak pengetahuan dan trend dalam industri masterbatch dari blog kami.

Bagi perniagaan yang beroperasi dalam sektor seperti pembungkusan, automotif, barangan pengguna, pembinaan atau tekstil, kebiasaan dengan Masterbatch berkemungkinan penting dalam proses pembuatan.

Dalam bidang pembuatan plastik, mencapai warna yang tepat dan meriah adalah elemen penting untuk kualiti produk dan daya tarikan visual.

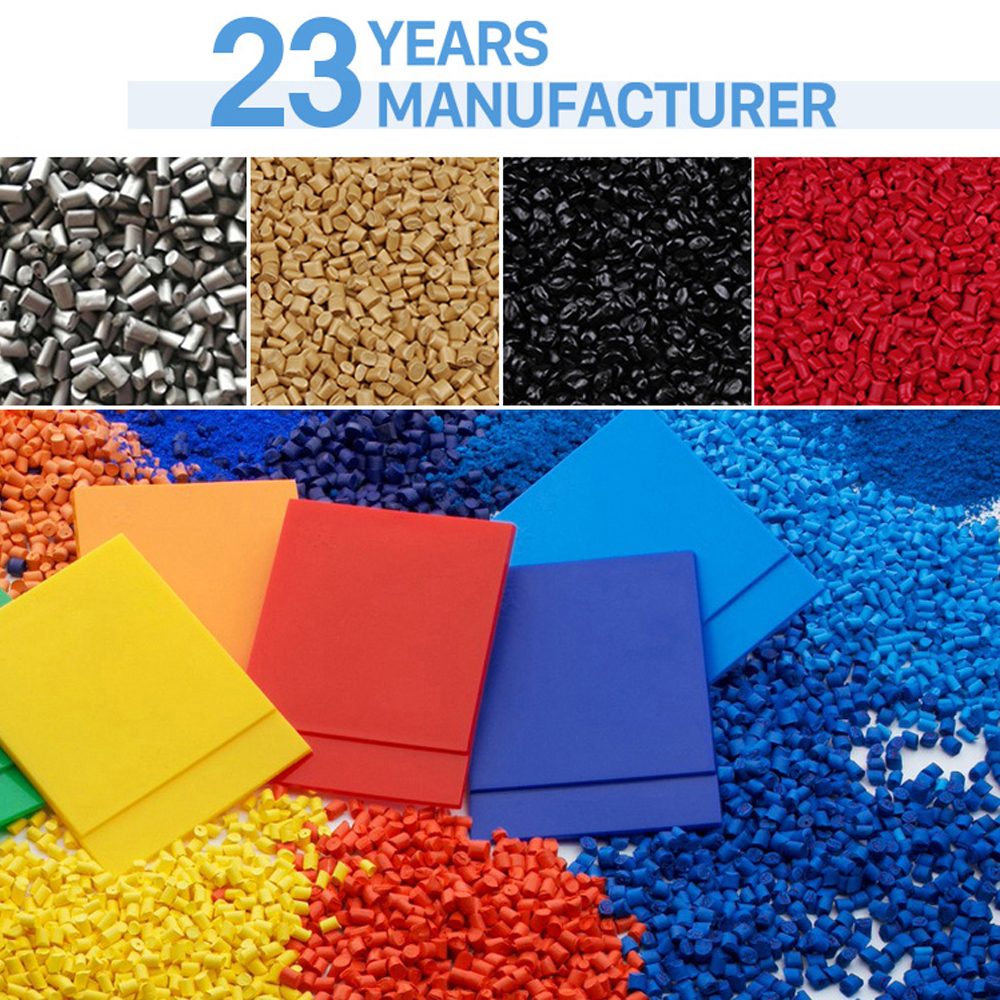

Memilih pengeluar masterbatch plastik yang betul adalah penting untuk memastikan produk yang berkualiti tinggi, tahan lama dan berprestasi baik. Kualiti masterbatch mempengaruhi warna, kekuatan dan prestasi produk keseluruhan. Dengan banyak pembekal yang tersedia, memilih yang betul adalah penting untuk kecekapan operasi dan kecemerlangan produk. Panduan ini mengetengahkan faktor utama, seperti kepakaran, kawalan kualiti dan penyesuaian, untuk membantu anda membuat keputusan yang tepat dan memilih pengeluar terbaik untuk keperluan anda.

©2023. Hak Cipta Terpelihara Pengeluar Masterbatch.

Pasukan kami akan menghantar tawaran terbaik dalam masa 20 minit.