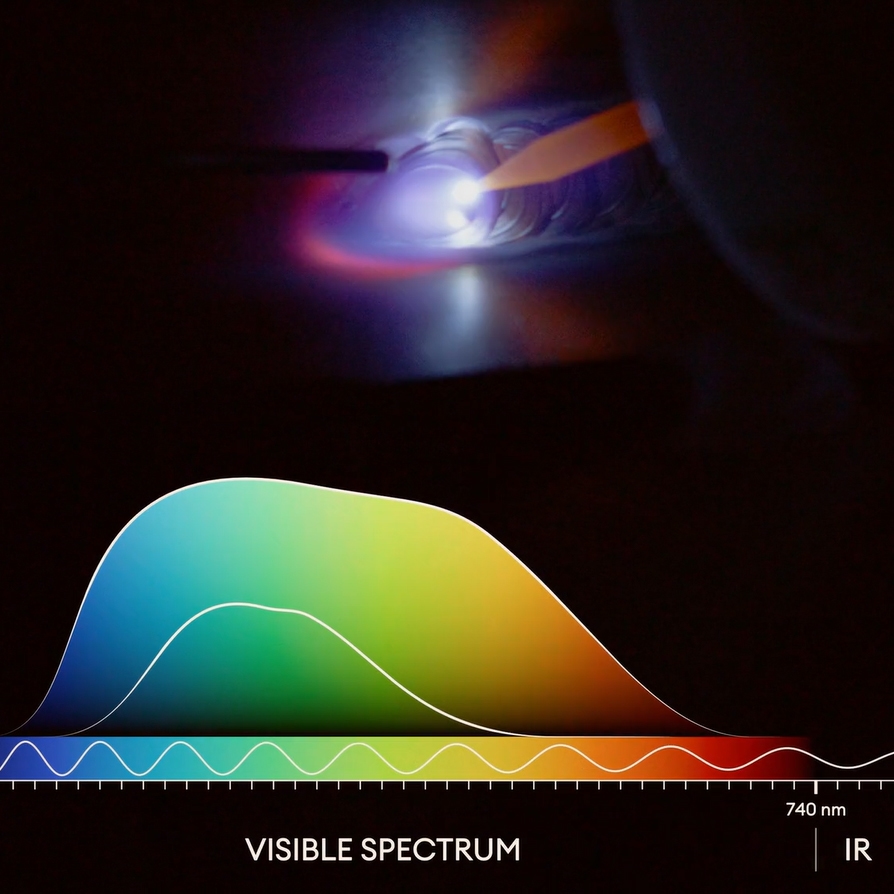

O que é um masterbatch infravermelho (IR)?

Um masterbatch infravermelho (IR) é uma mistura concentrada de aditivos especiais combinados com um polímero base para conferir aos materiais plásticos propriedades infravermelhas únicas. Dependendo da formulação, os masterbatches IR podem absorver, refletir ou transmitir radiação infravermelha.