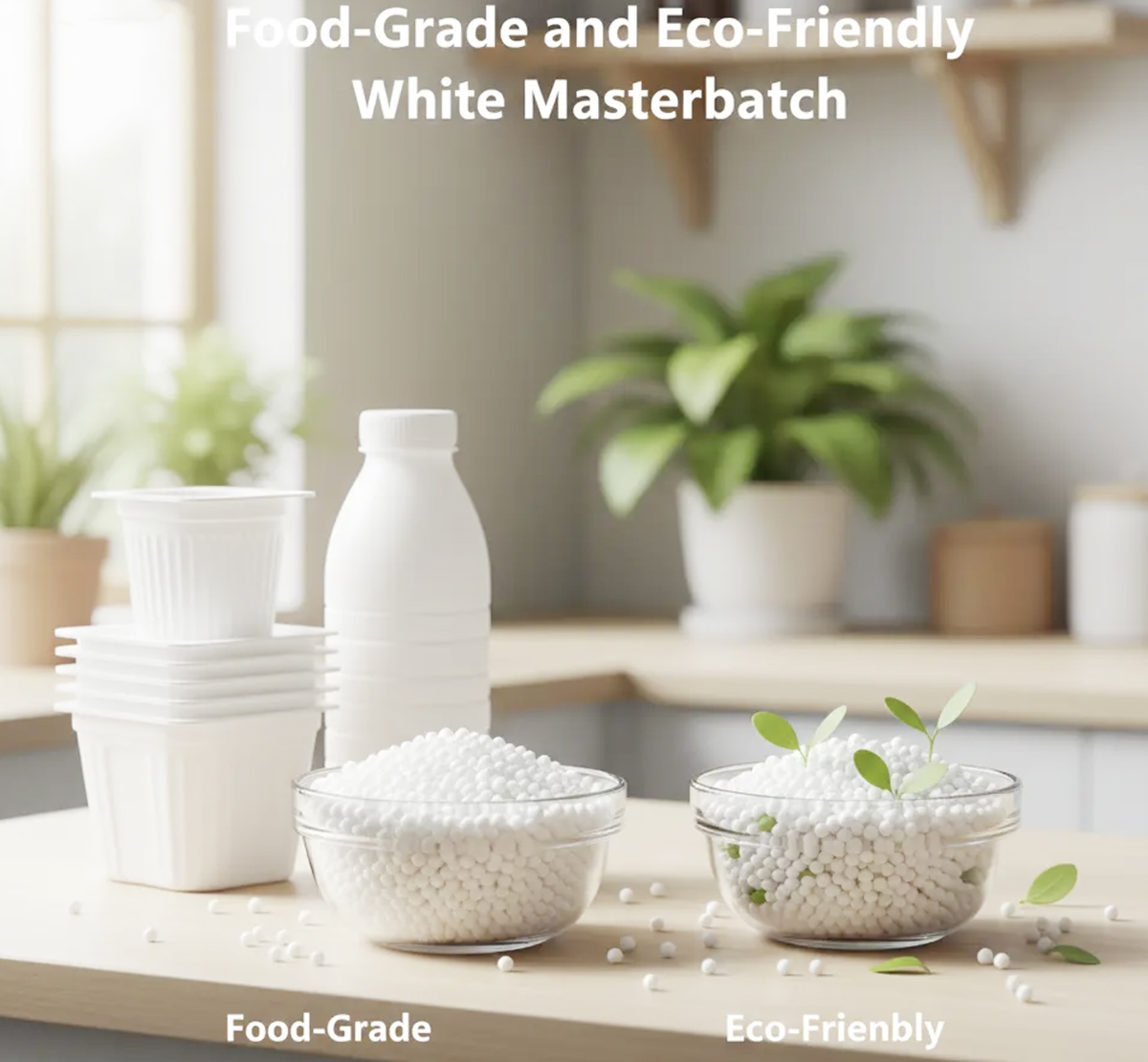

High-Quality TiO2 Concentrates White Masterbatch Supplier in China – Xinwancai

In today’s competitive plastics industry, achieving high opacity, excellent whiteness, and stable processing performance is essential for manufacturers worldwide. Choosing a reliable plays a critical role in ensuring consistent product quality and cost efficiency. Xinwancai Masterbatch is a professional masterbatch manufacturer in China.