Enhancing Plastic Properties through Additive Masterbatch

The realm of plastic manufacturing stands as a vibrant and forward-thinking domain where perpetual advancement remains pivotal.

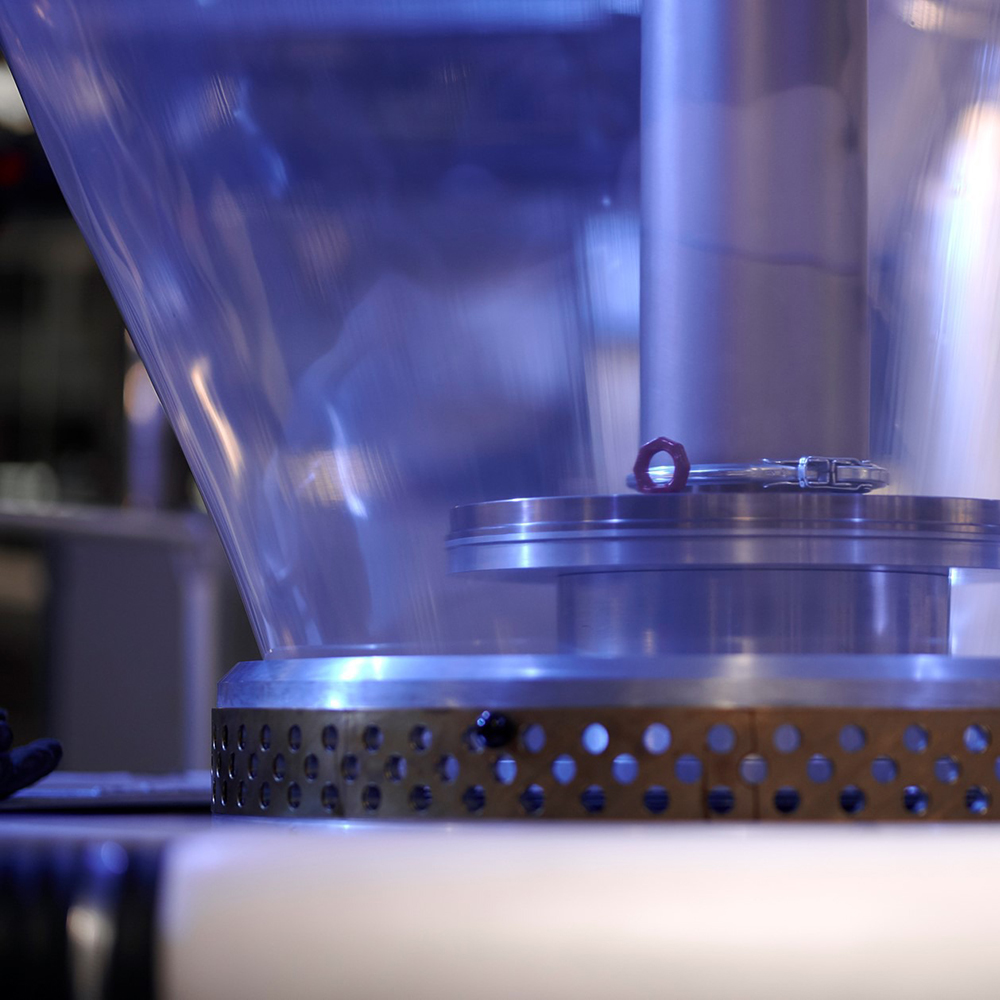

Pigments are typically characterized by their dry, solid, and powdery nature. Conversely, masterbatches represent a more advanced form of colorant, being concentrated blends of pigments and additives within a base polymer.

While both pigments and masterbatches can be employed to color polymer-based products, manufacturers often lean towards the use of masterbatch for several compelling reasons.

Masterbatches, arriving in pellet form, are easier to store, transport, and operate. In contrast, pigments, being in powder form, pose challenges in terms of handling.

Masterbatches prove more adept at being handled during the manufacturing process compared to pigments.

Pigments, being airborne, carry a significant risk of contaminating the production line and adjacent lines during manufacturing.

Masterbatch is produced in a compatible matrix or base polymer, facilitating the dispersion of color in the final product, whereas pigments may not disperse as effectively.

Matching the base polymer used in the masterbatch to the final product polymer is a straightforward process, contributing to a smoother melting process.

Despite the lesser amount of pigment present in a masterbatch, it compensates by requiring more of the same product due to the challenges associated with poor dispersion in pigments.

Masterbatch surpasses pigments in providing excellent color consistency for products.

Masterbatch offers the flexibility of including additive components in predetermined ratios, leading to fewer variations during processing compared to pigments.

A masterbatch can integrate additive concentrates, providing beneficial properties such as flame retardancy, optical brightening, and UV stability. This, in turn, reduces the quantity of feed entering the processing line.

Masterbatches afford greater control over the opacity of colored products, allowing for fine-tuning to meet specific requirements.

In summary, the advantages of masterbatches over pigments are multifaceted. From ease of handling to enhanced color consistency, reduced contamination risk, and the incorporation of additive components, masterbatches offer a comprehensive solution. Rapid Polymers stands as a reliable provider of an extensive range of masterbatches, ensuring a more efficient and dependable approach to coloring your polymers. Consider masterbatches for a heightened level of control and efficiency in your plastic coloring endeavors.

Learn more knowledge and trends in masterbatch industry from our blog.

The realm of plastic manufacturing stands as a vibrant and forward-thinking domain where perpetual advancement remains pivotal.

Here at Masterbatch Manufacturers, our commitment to providing valuable insights across diverse topics remains unwavering.

Selecting the right plastic masterbatch manufacturer is vital for ensuring high-quality, durable, and well-performing products. The masterbatch’s quality affects color, strength, and overall product performance. With many suppliers available, choosing the right one is crucial for operational efficiency and product excellence. This guide highlights key factors, such as expertise, quality control, and customization, to help you make an informed decision and choose the best manufacturer for your needs.

©2023. Masterbatch Manufacturer All Rights Reserved.

Our team will send back the best offer in 20 minutes.