Enhance Your Products with High-Quality White Masterbatch

White masterbatch is a versatile and essential component in various industries, offering a myriad of benefits for product enhancement.

Primarily designed to infuse a lustrous metallic sheen onto products, these masterbatches are meticulously crafted using a blend of metal powders or flakes seamlessly mixed with a carrier resin. The overarching benefit lies in their ability to confer a radiant metallic finish, elevating the visual appeal of the end product. This attribute holds particular significance in industries such as automotive and cosmetics, where visual aesthetics play a defining role in asserting market dominance.

At the heart of metallic masterbatches is their adaptability, offering manufacturers the freedom to customize and achieve an extensive array of metallic effects. From silver and bronze to gold and pink, the spectrum of possibilities is vast, enabling the creation of products with distinctive and captivating metallic finishes.

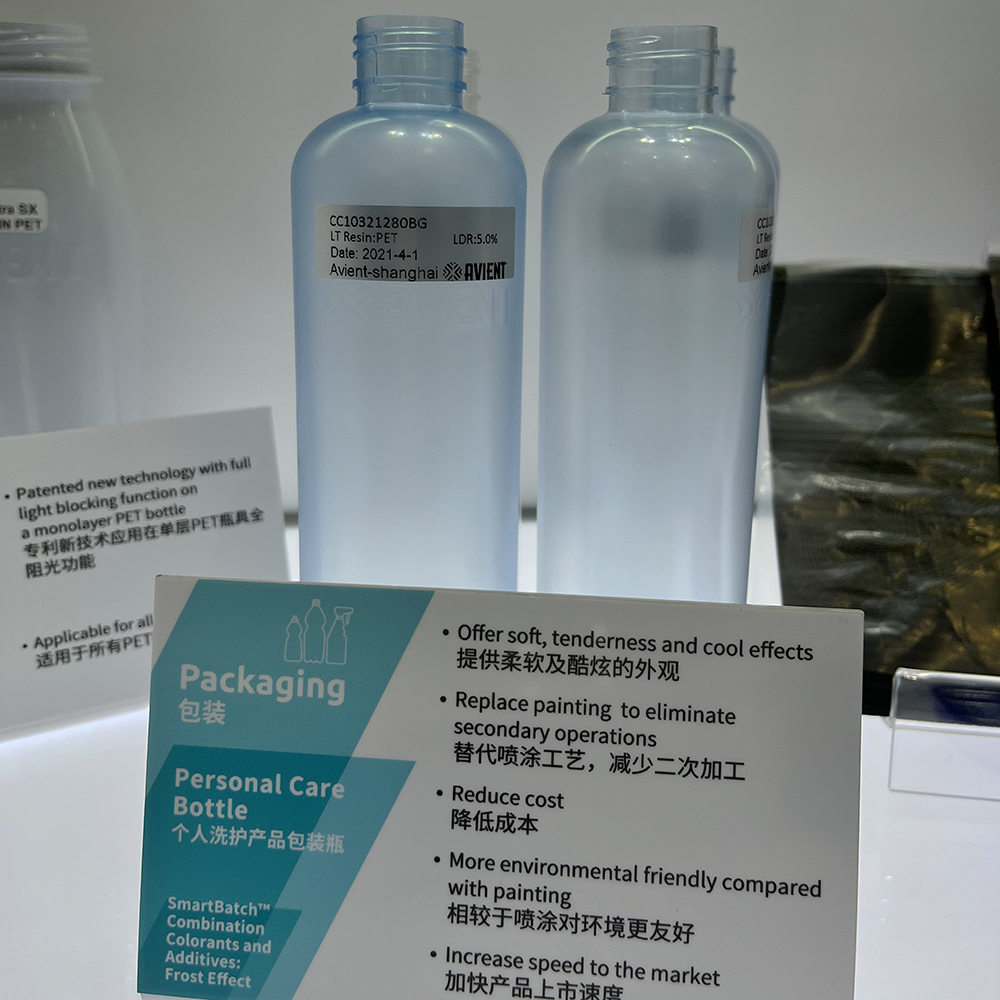

Beyond their aesthetic prowess, metallic masterbatches wield the capacity to enhance the physical and mechanical properties of the final product. For instance, strategically incorporating metallic masterbatches can amplify opacity, proving invaluable in light-blocking scenarios, especially within the food packaging sector. Additionally, these masterbatches contribute to heightened UV stability, fortifying products against degradation and discoloration when exposed to sunlight.

However, the manufacturing journey of metallic masterbatches demands a meticulous eye, particularly due to the elevated risk of contamination, a critical concern in sensitive applications like food packaging. Stringent quality control measures become imperative to ensure product safety and compliance with rigorous regulatory standards.

Nestled within this dynamic landscape is our state-of-the-art factory, standing as a beacon of excellence in the production of masterbatches tailored to diverse industry needs. With a rich legacy spanning over two decades, our unwavering commitment revolves around the core objective of delivering top-tier masterbatches at an affordable price point. Aligned with ISO 9001:2015 quality norms, our dedication to excellence has been duly recognized through prestigious awards, including the Economic Times Award, Plexconcil Export Award, IPSA Award, Business Gaurav SME Award, and more.

Our global footprint extends across 60-plus countries, where we strive not only to meet the unique requirements of our clients but also to provide an unparalleled customer experience. Anchored by prompt service, transparent policies, and timely delivery, we have forged enduring business associations with partners worldwide, underscoring our commitment to sustained excellence in the realm of masterbatch manufacturing.

Learn more knowledge and trends in masterbatch industry from our blog.

White masterbatch is a versatile and essential component in various industries, offering a myriad of benefits for product enhancement.

In the ever-evolving world of manufacturing, the demand for innovative and efficient solutions has never been greater.

The production of masterbatch involves a range of techniques and processes, each carefully executed to ensure the highest quality end product. This manufacturing journey can be broken down into the following crucial stages.

©2023. Masterbatch Manufacturer All Rights Reserved.

Our team will send back the best offer in 20 minutes.