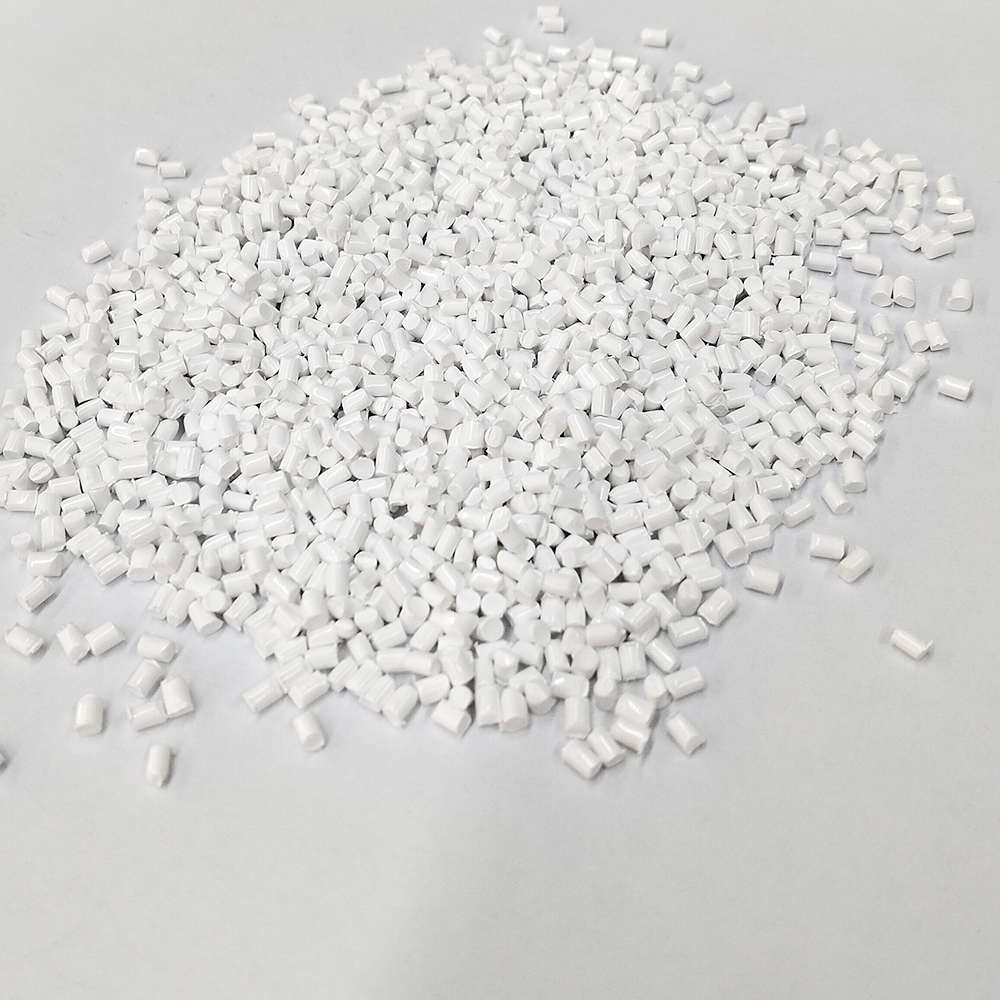

In this discussion, we delve into the realm of UV Masterbatches, a critical additive for plastic products constantly exposed to sunlight. Let’s explore the top benefits offered by UV Masterbatches:

Enhanced Stabilization

UV Masterbatch contributes to the improved stabilization of plastic products. Prolonged exposure to sunlight often triggers chemical reactions that degrade the plastic structure. The incorporation of UV Masterbatch minimizes this process, ensuring the structural stability of the product over an extended period.

Color Retention

Constant exposure to sunlight can cause colors to fade over time. UV Masterbatch prevents this fading, preserving the vibrancy and appearance of the plastic structure as if it were brand new.

Chemical Resistance

UV Masterbatch enhances the chemical resistance of plastic, providing additional strength when exposed to chemicals and substances that may compromise the overall integrity of the material. This is particularly valuable as common plastic products can rapidly disintegrate upon contact with certain chemicals.

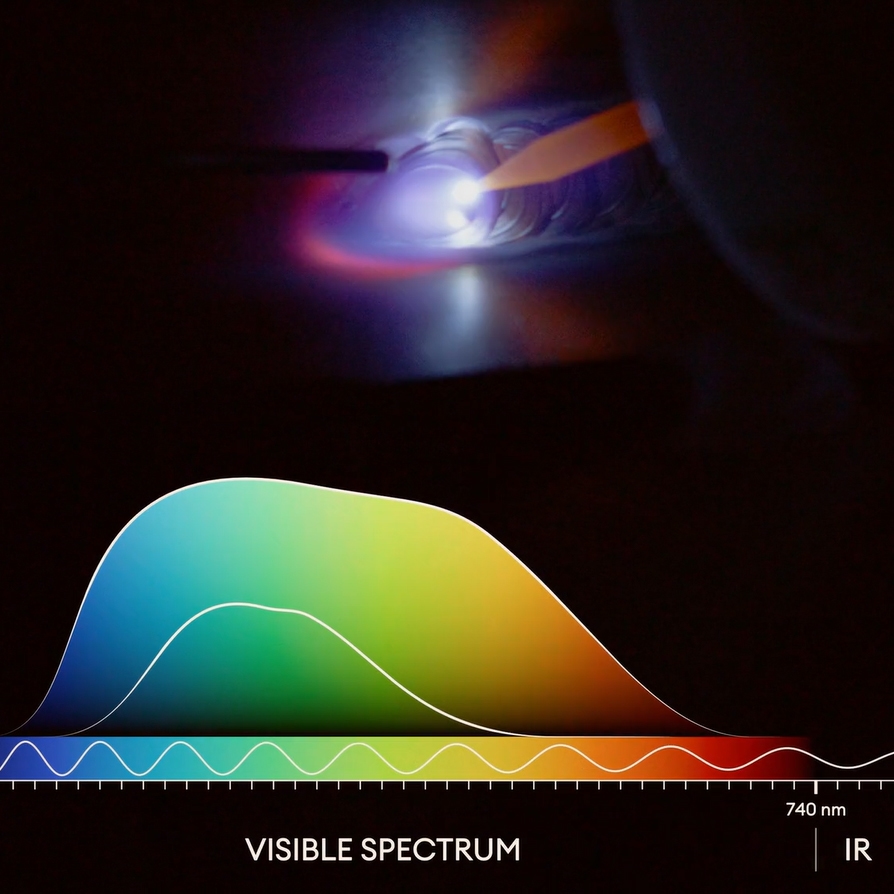

UV Radiation Absorption

The additive absorbs harmful UV radiation, serving as a protective shield for the plastic structure and whatever it houses. This feature ensures prolonged safety and integrity of the contents within the plastic product.

Long-lasting Durability

By incorporating UV Masterbatch, plastic products become more robust and durable, capable of withstanding harsh environmental conditions and maintaining their structural integrity over an extended period.

At our factory, our commitment revolves around innovation and excellence, prioritizing collaboration with clients to understand their unique needs and deliver tailor-made solutions. With two decades of industry experience, we have established ourselves as a leading masterbatch manufacturer. Our ISO 9001:2015 certification and recognition as a “One Star Export House” by the Indian government underscore our dedication to quality and excellence. As your partner, our factory not only provides expertise and insights but also acts as an advisor, collaborating with you from inception to achieve new heights of success. Choose our factory for a partnership that goes beyond expectations, ensuring the innovation and quality of your plastic products are elevated to unparalleled levels.