Exploring the Advantages of Polymer Masterbatches

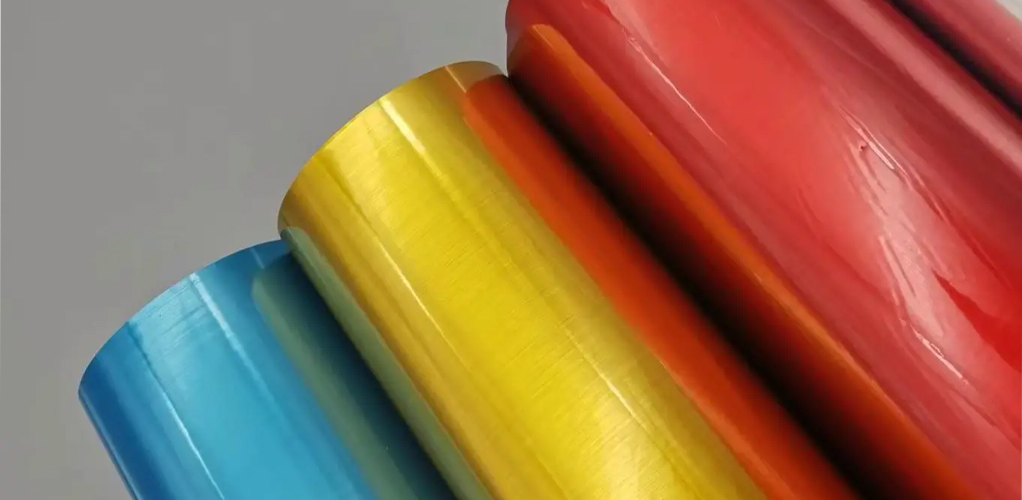

Polymer masterbatches, a concentrated blend of pigments, additives, and fillers, have become indispensable in the plastic industry for enhancing the physical and aesthetic properties of plastic products during the manufacturing process.