- +8615880211820

- [email protected]

- Tongan Industry Park, Xiamen

This Frost Effect Masterbatch product is made by processing polyolefin materials and abrasive agents through a special process. It can form a uniform and delicate frosted surface on the surface of polypropylene sheets or products, giving the sheets or products a diffuse, matte appearance. It significantly increases haze while ensuring good light diffusion, presenting a translucent, matte, and sophisticated frosted look. It is specifically designed for frosted PP products.

The product complies with GB9685-2016 National Standard for Additives Used in Food Contact Materials and Products, ensuring hygiene and safety, and can be directly used in food contact packaging materials.

| ITEM | Dosage | Melting Point | Hot Stability | Application |

| PP-WHP0596 | 4-8% | 125℃ | ≤300℃ | PP Sheets, Bottles, Cups Thermoforming |

| PET-L1145 | 4-10% | 300℃ | – | PET Sheets, Bottles, Cups Thermoforming |

1. For single-layer extruded sheets: Directly blend with PP raw materials, with a recommended addition amount of 10%-20%;

2. For multi-layer co-extrusion: It can be added directly to the surface layer at 100%, with a surface layer thickness of 30um-50um. The thickness can be adjusted according to the tensile strength of the PP sheet; the greater the tensile strength, the thicker the surface layer.

As an innovative functional material that can endow plastic products with unique texture, appearance, and uses, Frost Effect Masterbatch is becoming a popular choice in plastic product design due to its unique matte effect and versatility.

How does Frost Effect Masterbatch significantly increase haze and bring a delicate matte texture to plastic products? This starts with the raw materials that make up the Frost Effect Masterbatch. The Frost Effect Masterbatch is generally composed of carrier resin, abrasive agent, and functional additives. Through a special production process, including mixing, extrusion, and granulation, the abrasive agent is evenly dispersed in the carrier resin to form an easy-to-use granular product.

1. Consumer Perspective: Plastic products molded using Matte Frost Masterbatch have a comfortable feel and a more upscale appearance, fully meeting consumers’ requirements for high-quality appearance.

2. Functional Perspective: Matte surfaces are not only aesthetically pleasing but also have functions such as anti-slip, wear resistance, and fingerprint resistance, making them particularly suitable for products that require frequent touching or use.

3. Manufacturer’s Perspective: Frosted masterbatch has good compatibility with various plastic substrates and can be directly added to the production process without additional equipment or complex processes, reducing production costs.

4. Environmental Protection Perspective: The use of Frosted Effect Masterbatch can reduce subsequent surface treatment processes, is fully recyclable, and reduce environmental impact.

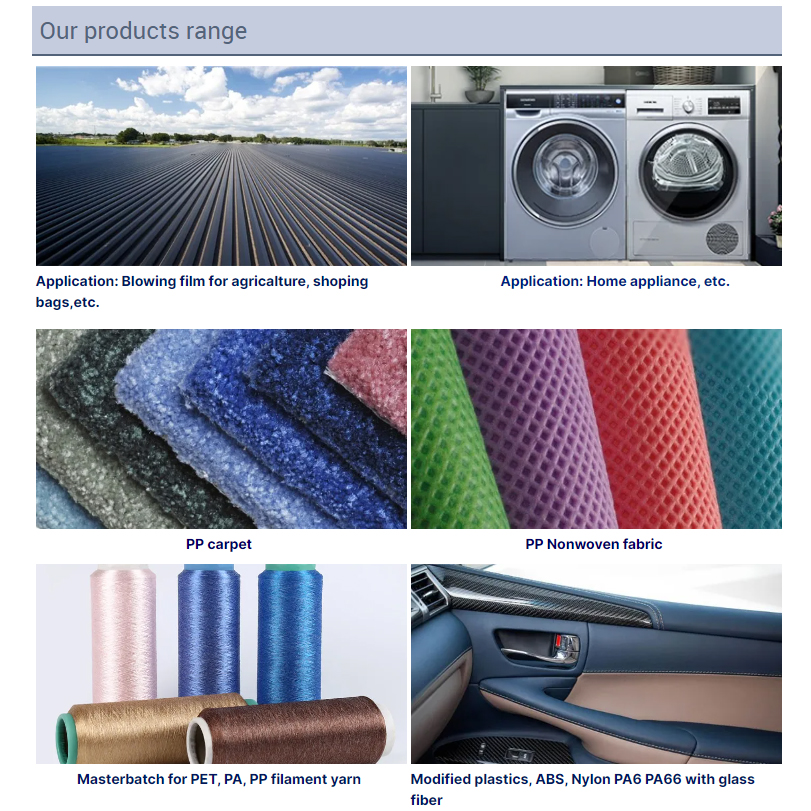

The application scope of frosted masterbatch is wide, not limited to tea and coffee beverage cups. Due to its unique properties, this product has been widely used in many fields. Below, we will discuss and learn about several typical application scenarios.

| Packaging Industry |

1. Food Packaging: A frosted surface can increase the texture of packaging, while also providing a certain degree of scratch resistance and extending the life of the packaging. Plastic cups in tea and coffee shops are the most widely used category.

2. Cosmetic Packaging: A frosted bottle or tube not only enhances the product’s premium feel but also effectively prevents slipping, making it convenient for consumers to use.

| Home Furnishings |

1. Tableware and Storage Boxes: A frosted surface is not only aesthetically pleasing but also increases slip resistance, improving the user experience.

2. Home Furnishings: For items like drawer handles and decorative panels, a matte finish enhances durability and tactile feel.

| Electronics |

1. Phone Cases and Protective Cases

Matte surfaces not only resist fingerprints but also provide a comfortable grip, making them popular with consumers.

2. Appliance Panels

For appliances like washing machines and refrigerators, a matte finish improves the overall quality.

| Automotive Parts |

1. Automotive Interiors

For items like dashboards and door handles, a matte finish increases durability and aesthetics.

2. Automotive Exteriors

For items like rearview mirror housings and trim strips, a matte finish enhances the vehicle’s perceived quality.

| Industrial Products |

1. Industrial Handles

Matte surfaces increase grip comfort and slip resistance, improving safety.

2. Equipment Housings

A matte finish is not only aesthetically pleasing but also effectively hides scratches, extending product lifespan.

As an innovative plastic additive, matte masterbatch is changing the appearance and performance of plastic products with its unique matte effect and versatility. Whether in packaging, home furnishings, electronics, or the automotive industry, frosted masterbatches can add unique value to products. As consumers’ demands for product appearance and functionality continue to rise, the application prospects of frosted masterbatches are vast. In the future, frosted masterbatches will develop in the following directions: First, multi-functionality, such as adding antibacterial and antistatic functions to the existing frosted effect to meet the needs of more application scenarios; second, environmental friendliness, with the targeted development of biodegradable or recyclable frosted masterbatches to reduce environmental impact.

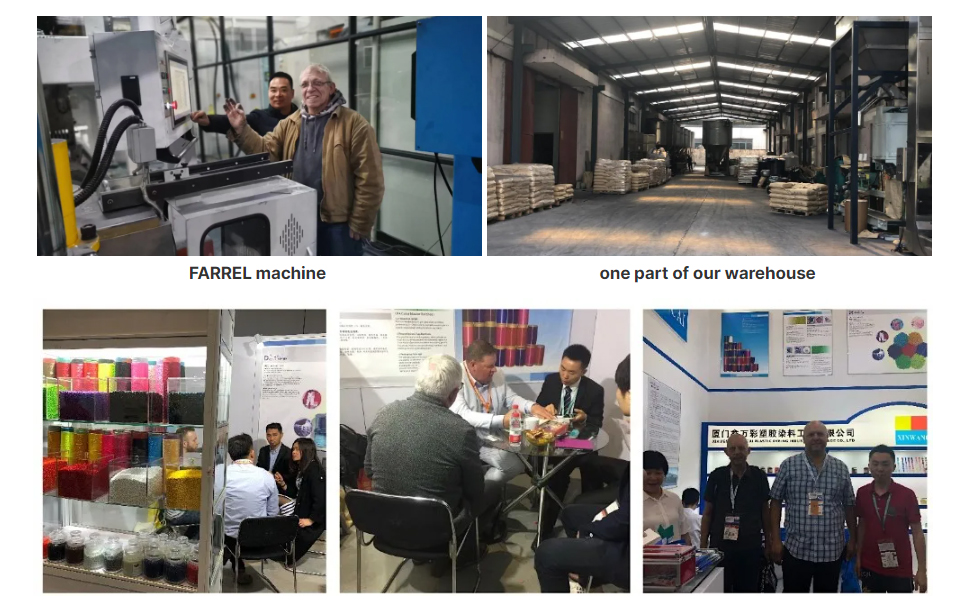

With 20+ years of expertise and ISO 9001:2015 certification, Iplastar is a global leader in innovative masterbatch solutions.

Advanced manufacturing systems

Eco-friendly and recyclable-compatible formulations

Responsive technical support & product optimization

Customization for color, frost intensity, and special effects

Strong supply capability for Indonesia, Pakistan, and global markets

Enhance your packaging with vibrant, colored frost effects—including frosted amber, frosted blue, frosted green, and more—without mold changes or costly surface treatments.

Whether you need frost effect masterbatch in Indonesia, frost effect masterbatch in Pakistan, or anywhere worldwide, Iplastar delivers performance, consistency, and creative freedom.

Contact Iplastar today for tailored Frost Effect and Deluster Effect Masterbatch solutions designed to elevate your brand identity while supporting sustainability goals.

Our company is over 20 years in plastic masterbatch industry, we specialize in researching and produce all kinds of Color masterbatches, functional masterbatch, fiberglass reinforced plastics and burning resistant plastic raw materials, located in Tong’an Industry Park of Xiamen City in China.

In conclusion, we are professional in producing all kinds of plastic masterbatch, including additive master-batch, functional masterbatch, PE flame retardant masterbatch, ABS flame retardant masterbatch, Anti-Oxygen masterbatch, Anti-UV masterbatch, Anti-bacterial masterbatch, Antiblock masterbatch, and some other additive masterbatches.

Our masterbatches find a multitude of applications across diverse industries. Whether in plastics, textiles, or various manufacturing processes, our masterbatches play a pivotal role in enhancing product quality and performance. With customizable formulations, they offer color consistency, UV protection, flame resistance, and more, making them the go-to solution for countless applications. From automotive parts to packaging materials, our masterbatches are the trusted choice for achieving superior results across a wide spectrum of industries.

Our custom masterbatches are designed to match specific polymers, ensuring optimal performance when incorporated into your selected material. We have the capability to produce masterbatches suitable for a variety of polymers mentioned below, and many more. If you’re working with a material that isn’t listed here, please don’t hesitate to reach out to our knowledgeable technical team to explore the possibility of meeting your specific needs.

Low Density Polyethylene – Somewhat more translucent than HDPE and considerably more pliable, primarily employed in flexible packaging, tote bags, pliable tubing, film applications, and similar uses. Like HDPE, it has limited transparency characteristics. It exhibits outstanding chemical resistance to alcohols, acids, and alkalis but has restricted resistance to hydrocarbon solvents and mineral oils. Prolonged exposure to UV radiation can initiate degradation.

High-Density Polyethylene – Featuring a somewhat milky-white appearance, this material finds wide application in rigid bottle packaging, injection-molded caps and closures, crates, and more. Its natural opacity can limit the degree of transparency attainable. HDPE exhibits superior chemical and solvent resistance when compared to LDPE.

PPCO Random & PPHO – A polymer with moderate clarity, employed in the production of caps and closures. It is also utilized for crafting household items, buckets, toys, and storage containers. Polypropylene offers flexibility without significant limitations on color or special effects. Random copolymer boasts greater clarity compared to homopolymer and is better suited for creating translucent shades.

PPCO Block – Similar to PPCO but enhanced for increased impact resistance. An additive renders the polymer white, resulting in high opacity. This characteristic may limit the achievable transparency.

Polyethylene Terephthalate (PET) – Polyester materials exhibit robust mechanical strength along with excellent chemical resistance and barrier properties. PET is frequently chosen for the production of carbonated beverage containers. Moreover, polyester can be spun and employed in textile manufacturing for clothing. PET is highly transparent, making it an excellent choice for translucent packaging, although a subtle hint of “yellowing” may impact extremely light tints.

Polybutylene Terephthalate – A crystalline thermoplastic engineering polymer frequently employed as an insulating material within the electronics sector. This substance belongs to the polyester category, showcasing a remarkable equilibrium of attributes and processing qualities.

General Purpose Polystyrene – Exhibiting a glass-clear appearance but possessing minimal impact resistance, this material finds its primary application in CD cases. Its notable clarity renders it suitable for creating translucent hues, although an occasional violet tint may be discernible.

High Impact Polystyrene – Derived from GPPS by incorporating an impact-enhancing agent to boost its resistance to impacts. This added component results in the polymer becoming white, and different formulations provide varying degrees of opacity. Typically employed in the fabrication of game pieces, toys, and similar items. Its pronounced whiteness can pose challenges when aiming for translucent coloration. Specialized alternatives like K-Resin and Styrolux are accessible in the market to attain the same level of translucency as GPPS.

Acrylonitrile Butadiene Styrene (ABS) – A more robust iteration of High Impact Polystyrene (HIPS) employed in high-value components. ABS exhibits greater durability compared to HIPS-made components, although it encounters similar challenges when attempting to achieve translucent colorations. Just like HIPS, ABS offers specialized translucent variants. Owing to its durability, ABS is commonly used in crafting casings for power tools.

Polyamide (6, 66) – Nylon represents a versatile grade extensively employed in mechanical construction and maintenance. Its popularity stems from its excellent blend of mechanical strength, rigidity, mechanical damping characteristics, and effective electrical insulation capabilities. Consequently, nylon is a preferred material for manufacturing electrical enclosures. PA66 serves as a common alternative to metal across diverse applications, with its chemical and physical attributes closely resembling those of PA6. PA6 exhibits superior impact resistance and resistance to solvents, albeit with a heightened susceptibility to moisture absorption.

Styrene Acrylonitrile Copolymer – Possessing transparency and outstanding chemical and heat resistance, SAN also boasts good rigidity, tensile strength, and flexural strength. Thanks to its high-gloss finish, SAN is commonly chosen for cosmetic packaging purposes. However, achieving light tint colors with SAN can be challenging due to the violet dyestuffs inherent in the material, which are utilized to enhance its visual appearance during manufacturing.

Polyethylene Terephthalate Glycol – PET with the incorporation of glycol. This glycol addition enhances flow properties but diminishes strength. PETG can be extruded to create bottles and can be formed into sheets for producing ‘blister’ style packaging.

Thermoplastic Elastomer (TPE) or Thermoplastic Polyurethane (TPU) – TPU finds diverse uses in applications such as automotive instrument panels, caster wheels, power tools, medical devices, as well as various extruded film, sheet, and profile applications. TPEs are employed across a wide range of applications in industries spanning automotive, medical, construction, electrical, appliances, packaging, and industrial sectors.

Frequently asked questions about our masterbatch

©2023. Masterbatch Manufacturer All Rights Reserved.

Our team will send back the best offer in 20 minutes.