The Ultimate Guide to White Masterbatch: Enhancing Plastics with High Opacity and Whiteness

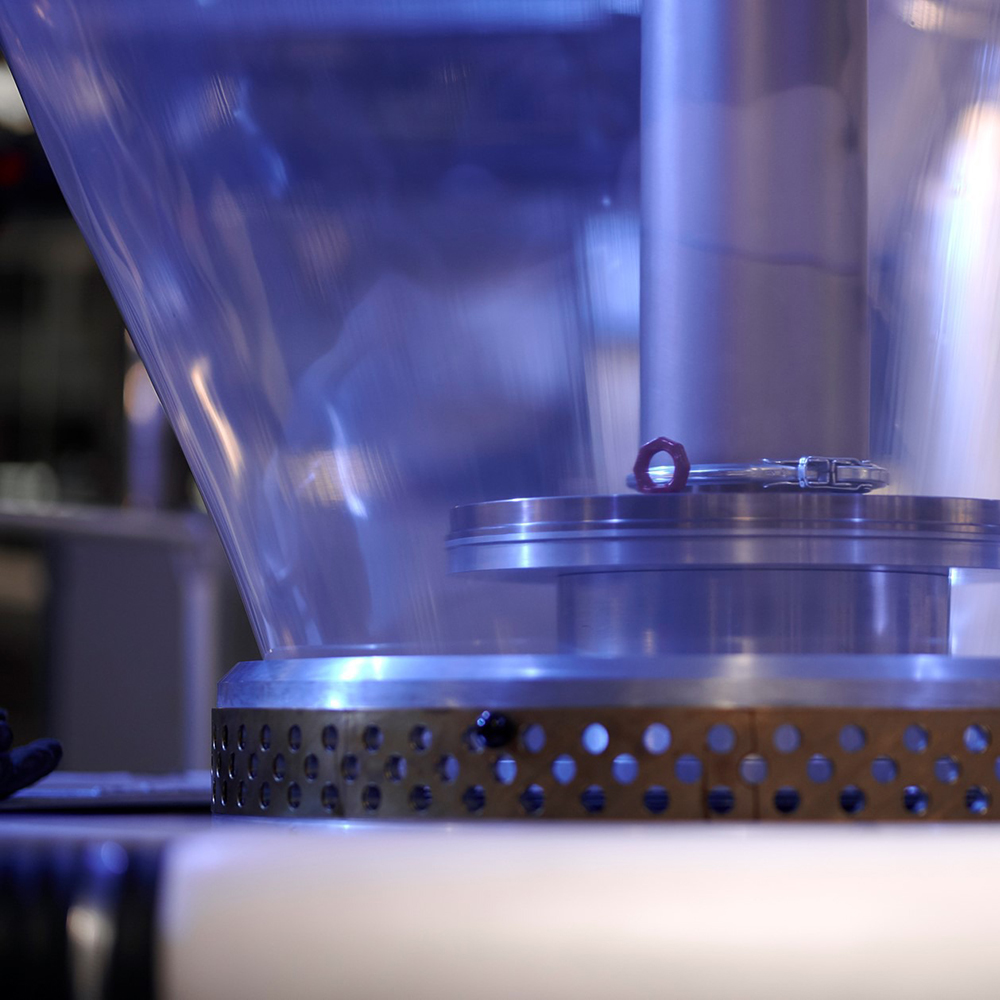

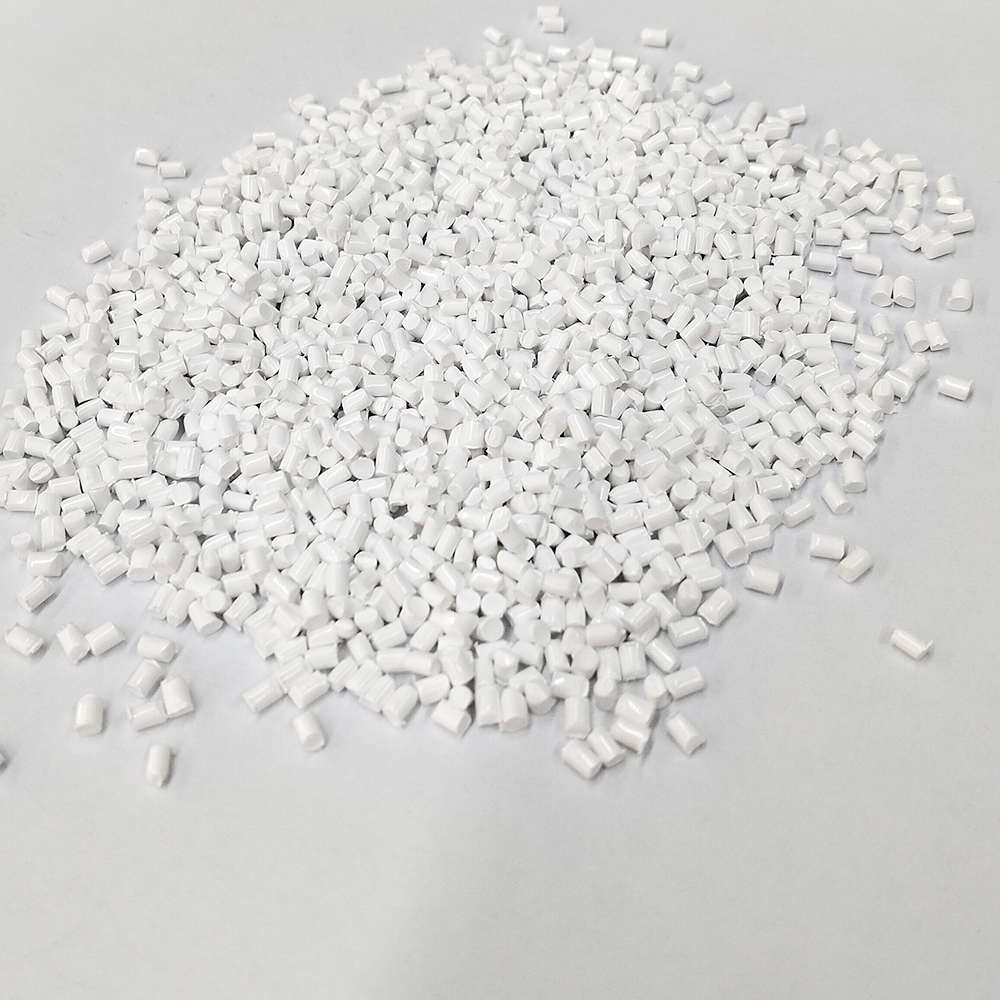

In the ever-evolving world of plastics, white masterbatch plays a crucial role in optimizing the quality and performance of plastic products. This article delves into the significance of white masterbatch, its applications, and its impact on the plastic industry.